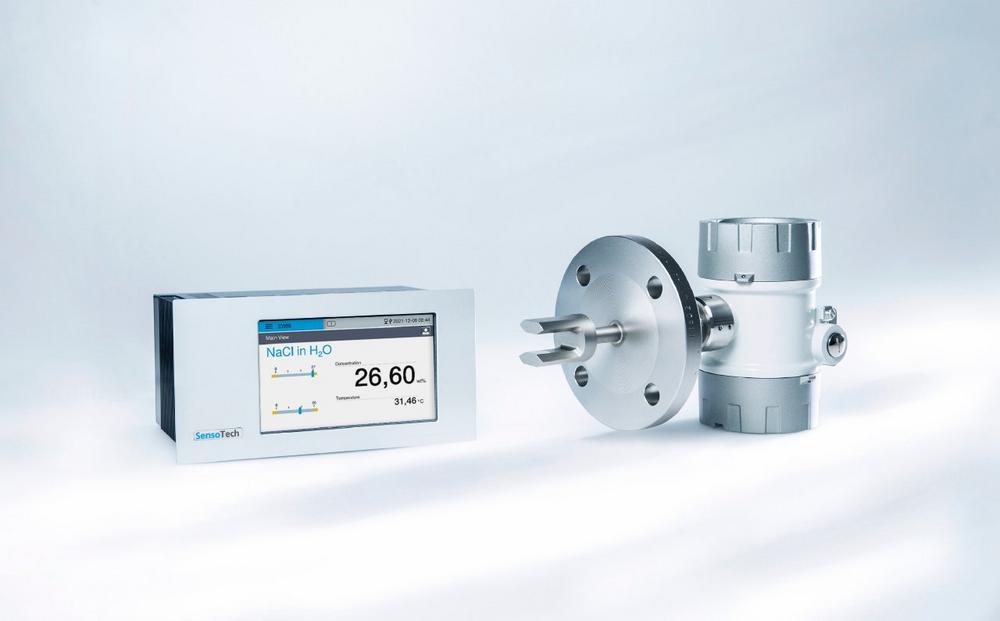

. Precision meets innovation: SensoTech is shaping the future of process analysis SensoTech is setting new standards in the world of industrial fluid analysis. With high-precision measurement technology and innovative sensors, the company is revolutionizing process monitoring and offering pioneering solutions for various industries. LiquiSonic® – The future of inline analysis SensoTech’s LiquiSonic® technology is […]

continue reading