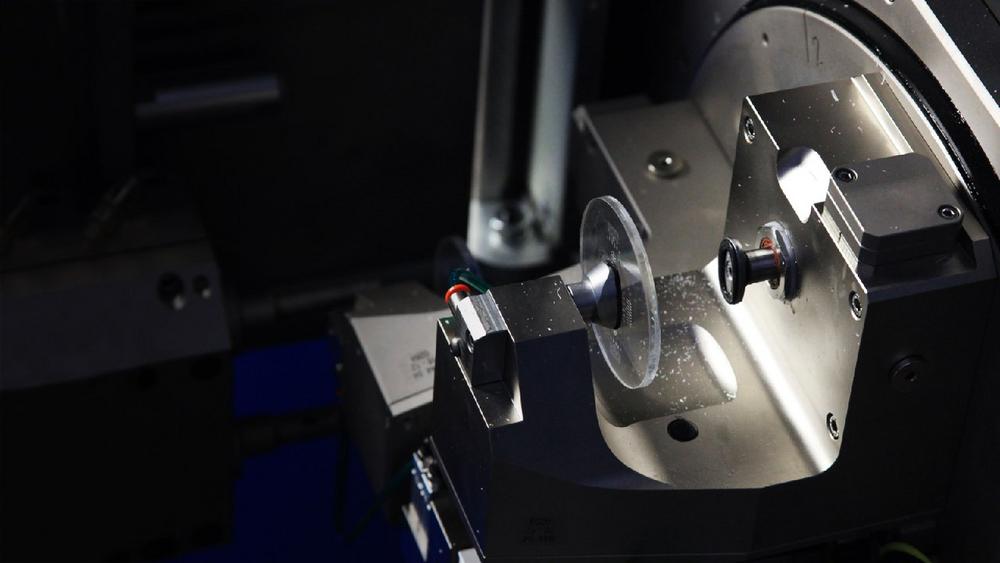

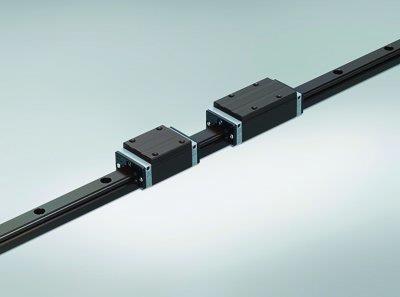

An Italian manufacturer of glass processing machinery is benefitting from the adoption of NH series linear guides from NSK. Now serving in a vertical drilling and milling machine for flat glass products, the NH30 (stainless steel version) linear guides overcome a number of challenges to deliver optimal performance for end users. The philosophy of this […]

continue reading