The iJaw was developed to address the problem of manual setting of clamping force by an operator. This manual action is typically done based on experience and “personal touch” and is therefore subject to human error and inaccuracies. Clamping force can often be set too high, due to safety concerns of unexpected workpiece ejections. Such over-clamping may damage the object. Moreover, without smart clamping, there is no way of monitoring loss of clamping force during operation, that can lead to additional faults in production caused by an inadequate grip.

Precise Measurement at the Clamping Point

The iJaw accurately measures variables such as clamping force, in real-time. It is now possible, for the first time, to get this valuable data from the rapidly rotating machine directly at the clamping point, thus enabling the most precise clamping force measurement. The uniqueness of this solution is the fact that the measurements are being transmitted wirelessly under very harsh conditions, rotating at thousands of RPM, from within a CNC machine during operation with much interference and environmental noise. This is achieved due to the ultra-high reliability and robustness of IO-Link Wireless technology which is the only wireless protocol designed specifically for such challenges.

These real-time measurements, now available during actual machining, enable precise setting and tuning of the machine and achieving optimal results with no wasted time on manual configuration and no damage caused due to human errors, as the positioning of the clamping system itself can now be much more precise.

Real time clamping force data also enables predictive maintenance and anticipation of upcoming repairs and/or tool wear-out in order to reduce unplanned downtime and streamline maintenance operations. In addition, data on clamping force can now be monitored and associated with production data per manufactured unit, to support QA and future tracking of quality.

Robust and Standard Design

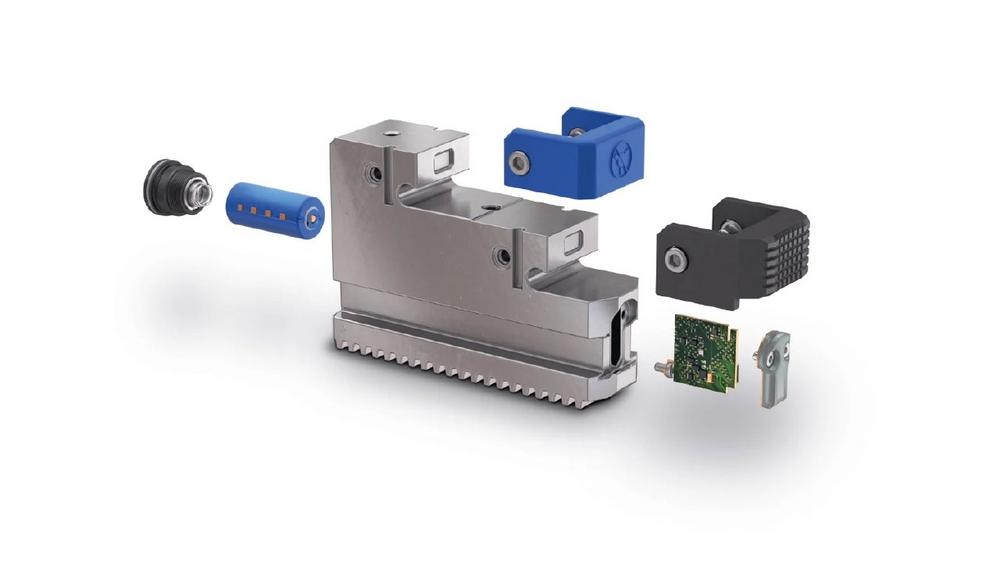

The iJaw houses an integrated force sensor along with an IO-Link Wireless embedded device, all packaged in a robust, hardened, waterproof (IP 68) steel formfactor including a high-heat resistant antenna to provide maximum protection. –

The measurements from the clamp are transmitted wirelessly to a Gateway which can be connected to the machine control system via a Profinet interface, or directly to IoT or cloud applications. The data can then be accessed by the control system (such as PLCs) and displayed on the Human-Machine Interface (HMI) tool. The iJaw can also be connected to the internet via a LAN interface on the gateway, enabling data to be sent to an IIoT server for processing, analysis and archiving.

To best meet the needs of the industry, the iJaw was created so it can be mounted on any chuck with a suitable jaw interface. The iJaw is available as a stepped jaw for straight or helical toothed chucks in sizes 215, 260 and 315. Röhm compatible chucks include the Duro-A RC , Duro-NCSE and Duro-NC power chucks with quick-change system and the manually operated chuck Duro-T. To adapt the jaws to different workpiece geometries, different replaceable hard and soft clamping inserts are available.

“Röhm is convinced, the iJaw will add a significant progress to the machine tool as it is today. We will see automation solutions we currently can hardly think of, since the iJaw gives us data of the machine process which weren’t available before. For transmitting the measurement data, we see IO-Link and IO-Link Wireless as the upcoming standard”, says Claus Faber, Head of Product Management and Marketing at Röhm.

As additional companies recognized the potential and benefits of the iJaw, Röhm has partnered with machine tool manufacturers DMG MORI, WFL and EMCO. These machine experts tested the iJaw on their machines and have already showcased it at recent events. DMG MORI presented the iJaw on a CTX beta 1250 TC 4A at a Pre-EMO 2021 event and WFL showcased the iJaw at EMO Italia 2021 as did Röhm.

“CoreTigo sees the partnership with Röhm as an integral part of the expansion of the IO-Link Wireless eco-system”, says CoreTigo’s CEO, Eran Zigman. “Once an industry decision-maker such as Röhm realizes the potential of IO-Link Wireless, a path is set out for the entire industry. This marks a great leap in advancing factory automation towards the vision of Industry 4.0.”

Smarter Wireless Clamping @ SPS 2021

Röhm is a key member of a distinguished group of industry leaders who have adopted the IO-Link Wireless technology and solutions offered by CoreTigo for advanced manufacturing. CoreTigo and Röhm will be showcasing the iJaw at the SPS 2021 exhibition in Nuremberg, Germany on November 23-25, 2021 – Hall 5, Booth 338. Other partners will be co-presenting their joint IO-Link Wireless solutions at CoreTigo’s booth including B&R, Camozzi Automation, Gimatic, Hilscher, Laumas, Protion, Vahle, Wittenstein and Zimmer Group. To set a meeting with CoreTigo, please visit https://www.coretigo.com/sps-2021.

About IO-Link Wireless

IO-Link Wireless is a deterministic, low latency (5 msec), highly-reliable and scalable universal wireless communication protocol. Based on the IO-Link IEC 61131-9 standard. It is designed specifically for factory automation, coexisting with other networks – both wired and wireless.

About Röhm

- Röhm GmbH, with its headquarters in Sontheim a.d. Brenz in Württemberg as well as production locations in Dillingen a.d. Donau (Bavaria) and St. Georgen (Black Forest), is specialized in the development, design, and production of high-precision, robust, and long-lasting clamping and gripping devices. The products are distinguished by being “Made in Germany.”

- Röhm clamping and gripping devices are used worldwide by almost all well-known manufacturers from the automotive industry and for railway engineering, watchmaking, medical technology, power engineering, and wood processing. Röhm has its own subsidiaries in France, Italy, Switzerland, Spain, Poland, USA, China, and Mexico.

- The company was founded in 1901 and quickly became known worldwide through the manufacture of drill chucks. To this day, Röhm develops and manufactures drill chucks at the Sontheim location that are used worldwide by almost all manufacturers on stationary as well as hand-operated electric tools for screwing and drilling.

CoreTigo is unbinding the industrial space by providing high-performance IO-Link Wireless communication solutions for machine builders, system integrators and industrial equipment manufacturers. CoreTigo’s products enable the design and retrofit of machines and production lines that were not possible before. These solutions increase flexibility, adaptivity and modularity, resulting in cost effectiveness, increased productivity, and downtime reduction. Embraced by industrial leaders, the IO-Link Wireless global standard, fit for harsh factory environments and motion control applications, provides cable-grade connectivity for millions of sensors, actuators, and industrial devices worldwide.

Contact: Gabi Daniely, Chief Strategy & Marketing Officer, +972-54-779-0466, gdaniely@coretigo.com

SOURCE CoreTigo

CoreTigo

Giborei Israel 5

IL4250405 Netanya

Telefon: +972-52-8536663

http://www.coretigo.com

Chief Strategy & Marketing Officer

Telefon: +972.54.779.0466

E-Mail: gdaniely@coretigo.com

![]()