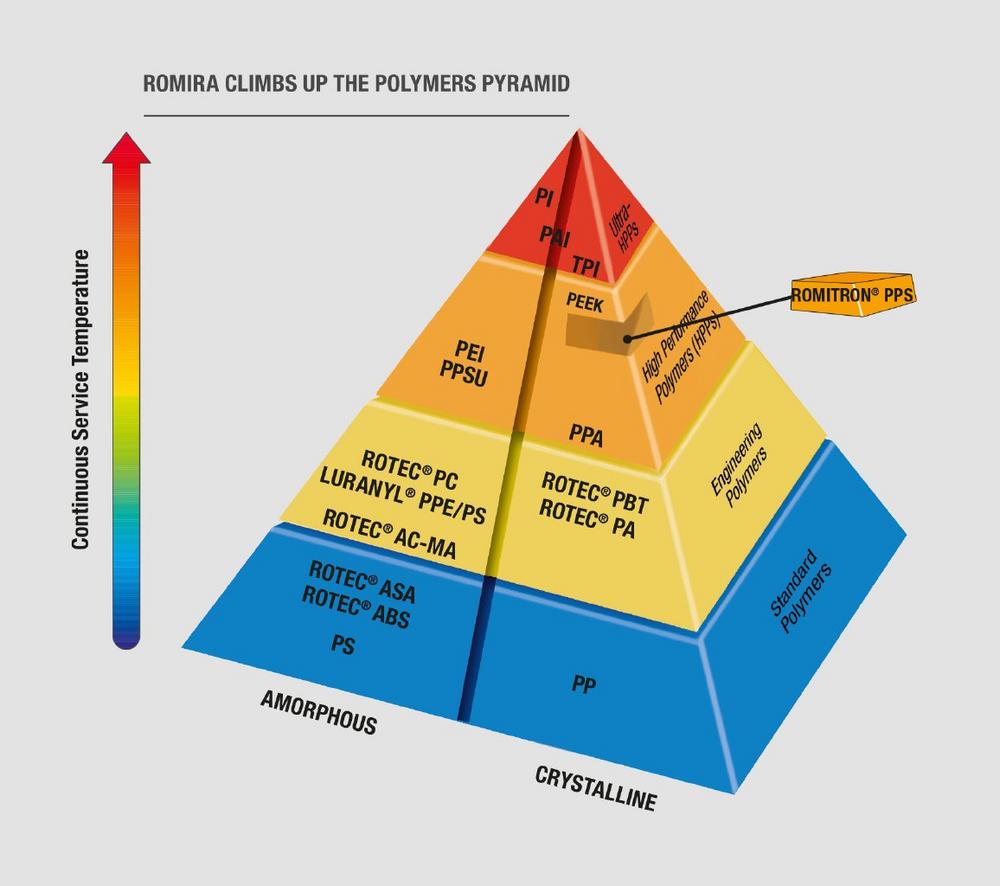

HPPs are generally classified as those polymers that have continuous service temperature exceeding 150 °C, along with superior mechanical and tribological properties and excellent chemical resistance. Examples are polysulfones, polyetherimide (PEI), polyether-ether ketone (PEEK), thermoplastic polyimide (TPI), polyphenylene sulfide (PPS), etc.

HPPs have a lot of industrial applications and are well spread in almost all key and expansive industries from automotive and aerospace to oil and gas and medical sectors. HPP Market is growing at a faster pace with substantial growth rates over the last years. The major growth drivers are improved performance, cost effectiveness, and lighter weight. As an example, these polymers are widely used in the automotive industry due to the continuing need for weight reduction, improved fuel efficiency, and more environmentally friendly attributes whilst enabling easier manufacture, faster assembly, and extended component life. In order to respond to this growing market demand, ROMIRA develops further by adding new HPPs to their product portfolio. To this end, ROMIRA has been equipped with new high heat extruders for both laboratory and large-scale production.

These advanced extruder lines enable ROMIRA to process a wide range of HPPs up to 450 °C. It is necessary to consider the special requirements for processing these polymers and the limitations of standard extrusion equipment. In addition to processing issues, there are matters of safety and economics.Furthermore, new development and processing technologists joined to ROMIRA with the aim of facilitating research and development process and to deal with possible technical issues.

ROMIRA now adds PPS as the first high performance polymer to their very broad portfolio of engineering polymers families. ROMIRA offers standard grade PPS compounds filled by glass fibre and/or minerals under its own brand name “ROMITRON®”.

ROMITRON® PPS compounds possess superior advantages over existing engineering polymers. The main feature of ROMITRON® compounds is its higher heat resistance that makes it an ideal material choice for demanding applications. ROMITRON® PPS has longterm service temperature of 210 °C, while other technical polymers cannot withstand temperatures above 130 °C continuously.

In addition to heat resistance, ROMITRON® compounds have extremely low moisture absorption and excellent chemical resistance. This enables ROMITRON® compounds to be used effectively in harsh-environment applications, where other HPPs like high-heat polyamides do not exhibit desirable performance.

With its high service temperature and excellent chemical resistance, ROMITRON® compounds can be used in a variety of applications such as under-the-hood automotive parts, fuel and cooling parts, headlight parts, high heat connectors and plugs, electronics and many other applications. In addition to standard PPS compounds, R&D activities are conducted on PPS-based specialties and blends to develop new solutions and meet specific demands of the customers.

Further information on the subject of “Coloring high-performance plastics“ can be found at

www.rowa-group.com/en/news

ROMIRA GmbH was founded in 1990 and is an affiliated partner within the ROWA GROUP. As part of this strong combine, ROMIRA sets standards for technical plastics with its profound competence and synergetic know-how.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

E-Mail: m.vaezi@romira.de

![]()