According to a survey by the Bitkom digital association, cyber attacks have caused damages of 102.9 billion euros throughout 70 percent of companies in Germany in recent years. According to the survey, the scope and quality of the attacks have increased dramatically. "The recreational hackers of the past have evolved into well-equipped and technologically savvy cyber gangs," Bitkom reports. POS terminals count among the targets. Sensitive data such as credit card numbers and PIN codes are temporarily stored on POS terminals to prevent data loss in the event that the payment process is interrupted. This data can be read by attackers if they gain access to the hardware using probes or mini-drills. An additional security element can be used which reliably prevents data loss.

3D-MID security caps increase the safety classification

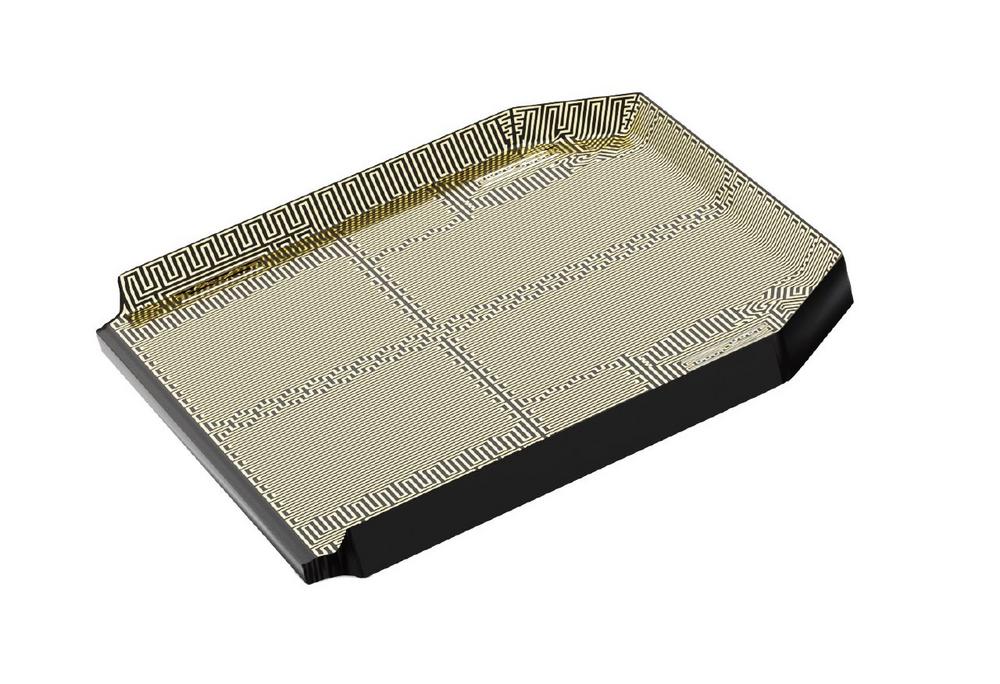

Electrical paths (traces) on the inside of the protective cap provide a very reliable additional security mechanism that protects against physical attacks. These traces form a closed circuit. They are so close together that it is practically impossible for an attacker to gain access. Any attempt to attack would either damage a trace and break the circuit or short out two traces. This causes the POS terminal to shut down immediately, resulting in the loss of cached data and rendering the device unusable.

The electrical traces are applied directly to the plastic parts of the security caps using the 3D-MID process. HARTING is the largest supplier of 3D-MID components (Mechatronic Integrated Devices) outside of Asia and offers all steps in the 3D-MID process under one roof. The injection-moulded circuit carriers replace conventional solutions that use a plastic carrier and printed circuit board. They do this by integrating the function of both parts into one MID. This reduces weight, reduces the number of components and lowers production costs, while at the same time improving security. This 3D-MID solution is particularly useful for POS terminals to improve security standards and to defend against hacker attacks.

Very small trace gaps improve security

Thanks to HARTING’s 3D-MID technological edge, customers benefit from compliance with the strictest PCIDSS (Payment Card Industry Data Security Standard) requirements. This solution differs from other suppliers of safety enclosures in that it has smaller trace widths. The closer the distances between the individual traces, the more difficult it is to manipulate the circuit from the outside. While most suppliers today can implement trace widths and spacings of around 300 to 500 μm, Harting offers 70 to 150 μm.

Lower costs thanks to automated production

HARTING’s 3D-MID solutions are more secure. Moreover, thanks to the extensive automation of the entire supply chain, they are also more cost-effective than solutions from many other suppliers. All production steps are carried out at HARTING’s own factory. This speeds up the process, increases the production yield and saves transportation costs. Even for products that are technologically less demanding, HARTING has been able to prevail over competitors from Asia.

HARTING is the only 3D-MID manufacturer in the world that has a laser system with three fine-focus optics of 50 μm. The fine-focus laser can achieve even smaller trace spacing of only 70 to 80 μm. This enables many traces to be created on the same component so that a higher packing density can be achieved. 3D-MID technology also allows for improved versatility in the shaping by creating flexible geometric contours in injection moulding and processing them with a laser for the electrical traces. Thus, rounded edges, elevations and transitions can also be produced.

About HARTING 3D-MID

HARTING 3D-MID covers the complete supply chain for 3D-MID technologies under one roof, including the development/prototyping of customised products, tooling, injection moulding, laser direct structuring, metallisation, packaging and final inspection. The production of mechatronic components for automotive engineering, industry, medical technology and sensor technology is the core of the business. HARTING is the largest supplier of 3D-MID components outside of Asia. HARTING 3D-MID is a division of the HARTING Technology Group, based in Espelkamp, Germany. http://www.3d-mid.technology/

HARTING AG

Leugenestrasse 10

CH2500 Biel 6

Telefon: +41 (32) 3442121

Telefax: +41 (32) 3442122

https://harting.com/DE/de

Telefon: +41 (76) 3909-074

E-Mail: Thomas.Hess@HARTING.com

![]()