The 3520 continues to grow the types of applications customers can solve with LMI’s stereo 3D snapshot sensor technology, including robot-driven quality control and inspection ofobjects with start stop/go motion in inline production systems.

The Gocator 3520 sensor is ideal for customers who need to perform:

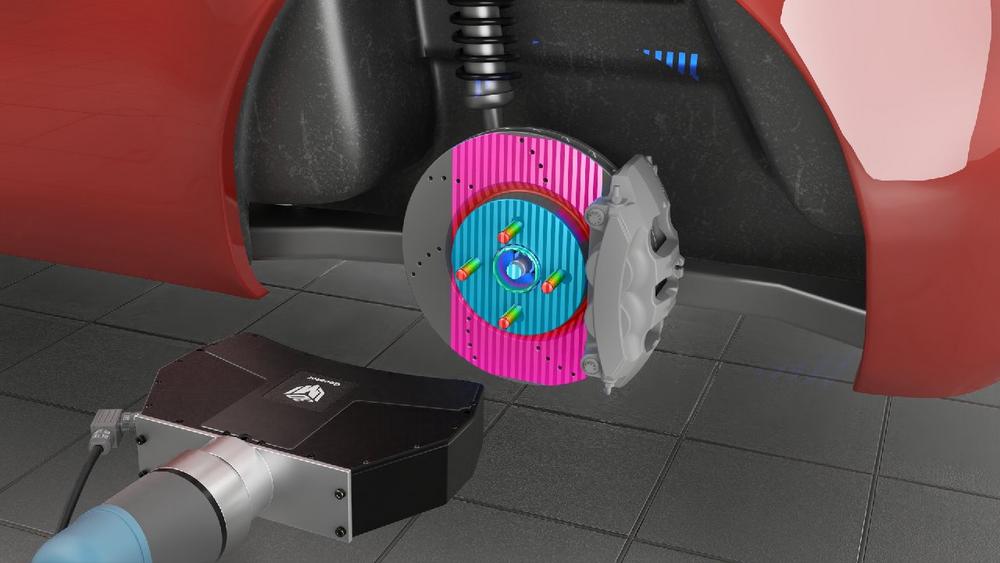

- Scanning and inspection of machined parts such as automotive powertrain (engine and transmission), body-in-white, wheels (lug nut location)

- Robot-mounted inspection applications that require stitching of multiple scans to generate complete 360º models of parts and assemblies for surface measurement and inspection

- Robot-mounted applications where the sensor provides XYZ coordinates to the robot for precision pick-and-place (e.g. structured/semi-structured bin picking)

- General factory automation applications that require extended fields of view and high-density 3D point cloud generation

Robot-Friendly

The sensor’s larger field of view and shorter clearance distance allow users to minimize the travel distances of the robot arm, increasing overall inspection coverage as a result. This design also offers a greater range of robot movement to support various scan angles.

High Intensity LED Projector and Stereo Camera Design

Gocator 3520’s high-intensity LED projector delivers the short exposure times and fast scan rates required to generate high quality scans with minimal motion blur caused by target vibration or movement jitter. The sensor’s 5-megapixel stereo camera design maximizes data capture by triangulating three ways to minimize occlusion.

“The Gocator 3520 is a new addition to our 5Mp stereo snapshot series that expands the field of view while maintaining high XY resolution and leveraging brighter projector output. This combination delivers smart 3D inspection into many new applications including robot-driven quality control and stop-and-go part verification,” said Terry Arden, CEO, LMI Technologies.

And like all Gocator 3D smart sensors, the 3520 doesn’t require an external controller or PC. Built-in 3D inspection software allows for out-of-the-box measurement and seamless integration with existing systems. By installing the sensor on a robot arm, customers can perform built-in hand-to-eye calibration between robot and sensor to easily achieve smart robot inspection leading to a path of greater factory automation.

Gocator 3520 is now available for order at order@lmi3.com. Write to contact@lmi3d.com for any questions you have regarding this new product.

For additional information on this new sensor, visit the Gocator 3520 product page on our website.

As the global leader in 3D scanning and inspection, LMI Technologies works to advance quality and productivity with 3D sensor technology. Our award-winning, FactorySmart® laser, snapshot, and line confocal sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies. Unlike contact based measurement or 2D vision, our non-contact solutions add 3D shape information that is critical to achieving 100% quality control.

To learn more about how LMI’s inspection solutions can benefit your business, we invite you to contact us at contact@lmi3d.com or visit us at www.lmi3d.com to explore the possibilities of smart 3D technology.

LMI Technologies

Warthestraße 21

14513 Teltow

Telefon: +49 (3328) 9360-0

Telefax: +49 (3328) 305188

http://www.lmi3d.com

Regional Marketing Manager – EMEAR

Telefon: +49 (3328) 9360161

E-Mail: vgermann@lmi3d.com

![]()