To determine the position of the strip during operation, an appropriately selected sensor solution is required for a wide range of boundary conditions. EMG often uses inductive methods (EMG SMI), but for various applications, optical positioning of the edge or centre of the strip is the only solution. This is particularly true for uncoiling and recoiling processes where the distance to the strip must be sufficiently large or for trimming shears, where the greater accuracy of the measurement plays a major role.

Optical strip edge or strip centre measurement EMG EVK/EVM

The corresponding solution in the EMG product portfolio is called "EMG EVK or EVM". These so-called "sensor positioners" for edge detection (EVK) or centre determination (EVM) work with high reliability and are robust against external interference.

Functional principle and advantages

The strip edge is detected by the above-mentioned movable sensor positioners, which are equipped with high frequency alternating light receivers (light barriers of type LS 13/14) protected from external light. If a lateral displacement of the strip edge occurs due to strips changing width or due to the horizontal movement of the strip, this displacement is detected by the light barriers. As a result, the light barriers are moved by a motor so that the strip edge is always in the centre of the measuring system’s field of vision. In addition, the strip position is corrected via the actuator of the control circuit (servo valve or electric servo cylinder) and the steering roll or coiler until it corresponds to the target position again. By using high frequency alternating light transmitters, the systems are insensitive to external light influences, whether from artificial (e.g. moving light sources on the crane) or natural light sources (e.g. sunlight through the hall skylight). The reference measurement principle is also used to compensate for contamination of the light emitters.

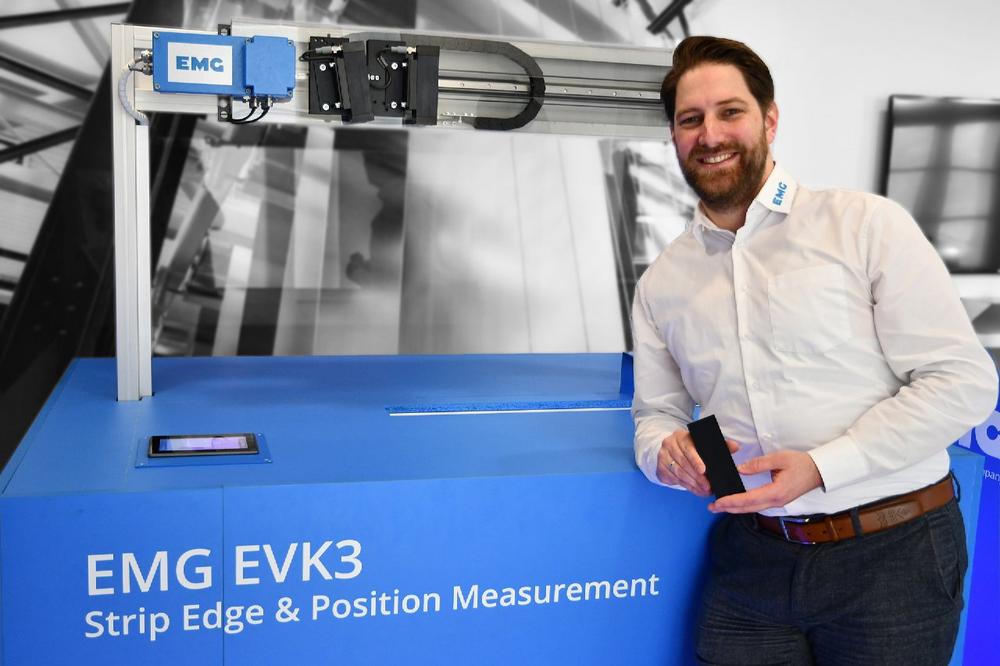

The new generation EMG EVK3/EVM3

EMG EVK and EVM solutions have been used successfully by hundreds of EMG users worldwide for decades. The new generation offers EMG users significantly improved and simplified handling. These innovations make commissioning and using the system more efficiently and user-friendly.

Operation and performance

The simple adjustment via a web browser and digital potentiometers, which enable quick and intuitive operation, is worth emphasising. The new, four times faster moving carriage with the LS13/14 receivers and a wear-free encoder ensure improved performance and a longer service life for the system. In addition, the new generation guarantees a continued high measuring accuracy of +/-1 mm and a large measuring distance of up to 4 metres.

Compatibility and interfaces

Another advantage is the trouble-free compatibility with the predecessor model EMG EVK2/EVM2. This makes the transition easier for existing users, as the new EMG EVK3/EVM3 sensor can be installed at the same mounting points as the EMG EVK2/EVM2 generation. The electrical connection is also straightforward, as existing cables from the EMG EVK2/EVM2 system can be used directly. In addition, no software adjustments are required in the control electronics, which further simplifies the changeover to the new system.

Conclusion from our product manager Jens Kathol

"I am completely convinced of the capabilities and user-friendliness of our new EMG EVK3/EVM3 series. It represents an advanced solution that stands out both in terms of handling and technical performance and offers our customers real added value. With this new generation of sensors, we can fulfil your requirements for optical measuring systems in strip guiding in the long term." – Jens Kathol, Product Manager Strip Guiding Systems. To summarise, the EMG EVK3/EVM3 series offers an advanced, user-friendly solution with a clear position in terms of both handling and backwards compatibility.

Curious?

Would you like to know more about EMG EVK3/EVM3 and the associated application possibilities?

Please feel free to contact our sales department, our international sales organisation or our product manager Jens Kathol (jens.kathol@emg-automation.com) directly at any time. We look forward to hearing from you!

Downloads:

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Product Marketing

Telefon: +49 (2762) 612-282

E-Mail: Claudia.Schreiner@emg-automation.com

![]()