EtherCAT P is a further development of the globally established and standardised EtherCAT technology. The special feature of EtherCAT-P is the combination of superfast EtherCAT communication with the 24V power supply. Data and power (Us) for system and sensor supply with 24V and 3A are provided on a two-wire data pair.

The second data pair provides data and the peripheral voltage (Up) for the supply of the actuators. This direct coupling of the supply voltage to the 100 MBit line for EtherCAT-P enables a compact and cost-effective device interface.

Since the supply lines are no longer required, this is referred to as a "single-cable solution".

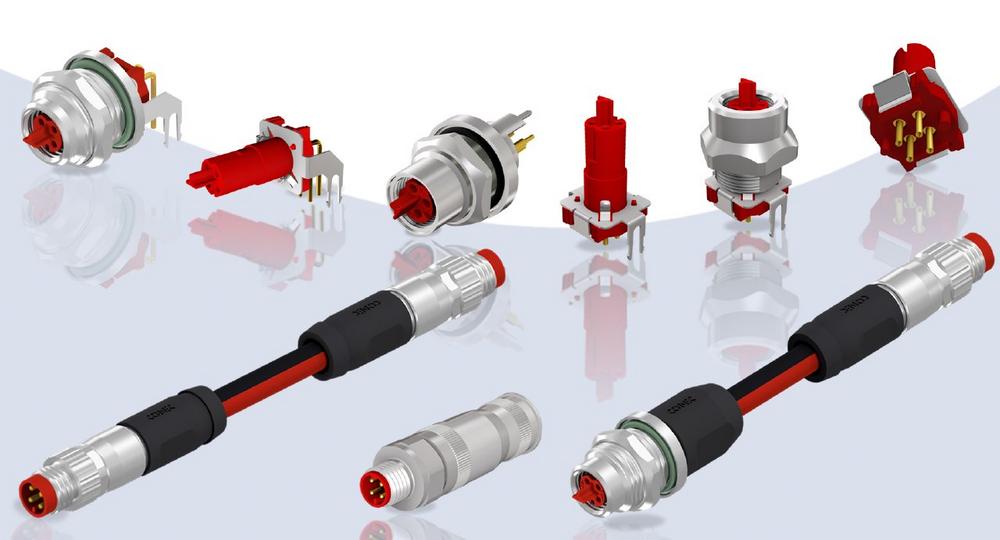

In order to make it impossible to connect with other standardized M8x1 connector systems, a new coding has been developed for this application and standardized in IEC 60176-2-114 under the term "P – Coding". Special features of this coding are the red colouring of the contact carriers and the leading T-contour on the front face of the coupling contact carrier, which prevents connecting with other codings.

Connectors overmoulded:

Currently, shielded overmoulded designs with cable quality GBX, PUR, UL Cat 5e, 4xAWG22, are available in the standard lengths. For the 100 MBit device connection almost exclusively male-male patch cords are used.

Connectors field attachable:

Field attachable connectors are available as female and male variants in axial design, either with screw (Female and Male connector) or crimp (male connector) termination.

Flanges for direct PCB mounting:

An extensive product range for device connection is available here, so that the user has many variable installation options. The continuous shielding from the flange housing to the circuit board is realised with a punched sheet metal plate. Moulded contact tongues form the radial connection to the flange housing, the connection to the printed circuit board is made by means of latching elements with subsequent soldering. The materials used are suitable for wave soldering.

A special flange version is the version with moulded cable and a further plug on side B, preferably P-coded. Ideally, this can be used for wiring through a wall, e. g. a switch cabinet.

Advantages:

- Very small connector system with small installation space for fieldbus transmission technology

- Power and data on one data pair

- Variable installation and connection options on the device side

- Good chemical resistance of the connector

- High degree of protection IP67

- Robustness

Fields of application:

- Drive technology

- Communication technology

- Automation technology

- Machine manufacturing

- Housing and device construction

- Control technology

- Industrial interfaces

For more than 40 years, CONEC Elektronische Bauelemente GmbH has been developing, producing and marketing high-quality connectors, patch cable and single ended cable as well as enclosure technology.

CONEC products are used in automation, telecommunications and energy technology, machine manufacturing, agriculture and medical technology, transportation and the aviation industry.

The headquarters in Lippstadt has a large research and development department, its own tool-making department, a CNC-turning department and a synthetics injection moulding plant.

As part of the Amphenol Group, CONEC participates in the growth and development opportunities of a globally active group and at the same time acts flexibly and quickly as a medium-sized company in order to optimally adapt to changing customer needs.

In addition to a variety of connectors for all current standards, our particular strength is the integrated moulding of components and assemblies and the development of customized solutions.

CONEC is a global player with its own subsidiaries and/or production sites in Canada, China, the Czech Reblublic, Poland, Slovakia and Mexico.

The product portfolio includes connectors of the following categories:

• D-SUB/IP67 D-SUB Connectors

• IP67 RJ45 / USB / Mini USB / Fiber Optic LC Duplex

• CONEC Hybrid Connectors

• Connectors for agricultural and construction machines

• Circular Connectors

• PCB Connectors

• Customer specific solutions

CONEC Elektronische Bauelemente GmbH

Ostenfeldmark 16

59557 Lippstadt

Telefon: +49 (2941) 765-0

Telefax: +49 (2941) 765-65

http://www.conec.com

Marketing Communications Manager

Telefon: +49 (2941) 765-350

Fax: +49 (2941) 765-65

E-Mail: Katja.schade@conec.de

![]()