50 years in just one system

"Engineering Base is the first system to achieve this integration and unites the entire life cycle of substations, from the project idea and detailed planning through to construction and maintenance," explains Michaela Imbusch, the product manager responsible for the Power Transmission & Distribution division. All disciplines, now including control technology, can simultaneously use the entire engineering scope of the platform, build their own libraries, find objects in an instant, track their history and much more. Changes are immediately comprehensible for everyone involved. "Files can never be used to correctly map a substation over the 50 or so years it is in operation. In EB’s data model, on the other hand, all objects and their attributes can be edited directly and centrally at any time," she emphasizes. Such a digital twin does not disappear like files, frozen in folders or management systems, but remains dynamic and up-to-date.

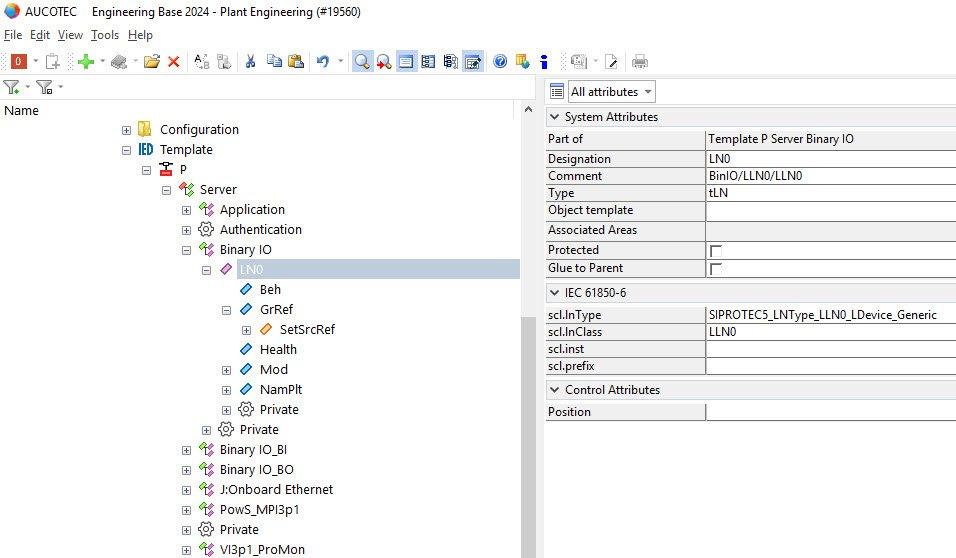

The DNA of the substation

IEC 61850 is more than just an international standard for the vendor-neutral description of devices in substations and with specifications on how these devices may communicate. It forms the DNA of the systems, so to speak; entire congresses are devoted solely to it, and it causes headaches for operating companies. This is because the digital substations of the future, which now need to be planned quickly and in large quantities due to the enormous pressure to decarbonize, will mainly contain servers instead of rows of control cabinets. Data bus systems then handle the exchange of information from the field to the control system. This makes IEC 61850 even more important.

Without the physical wiring of the devices, circuit diagrams or terminal block diagrams are also no longer required. As a result, document-oriented engineering tools that rely on circuit diagrams for detailed information are becoming much less important. "Thanks to data centering, EB can also work purely alphanumerically. There is no need to draw a single plan to define details," explains Imbusch.

A big step

EB has been supporting IEC 61850 for years: by integrating the Substation Configuration Tool (SCT) developed by Aucotec partner H&S, by understanding the required Substation Configuration Language SCL and by being able to generate the normative SCD file (Substation Configuration Description). "With the new big step, EB can do all this on its own, without XML outputs and transfers or tool synchronization. The functional data models of the Intelligent Electrical Devices (IED) are directly linked to their hardware models. The system landscape is now significantly streamlined and the strain on IT is reduced," emphasizes Michaela Imbusch. Linking the hardware and software worlds is also a considerable relief for project managers. "Always knowing where the data is and being able to rely on it being up to date is anything but a matter of course," says the product manager.

Aucotec AG has more than 35 years’ experience in the development of engineering software designed for use throughout the life cycle of machinery, plant equipment and mobile systems. Solutions range from flow diagrams and process-control/electrical technology for large-scale plant systems to modular on-board power supply units designed for the automotive industry. Software supplied by Aucotec is currently in operation throughout the world. In addition to the headquarters near Hanover, the Aucotec Group includes six other locations in Germany as well as subsidiaries in China, India, Malaysia, South Korea, the Netherlands, France, Italy, Austria, Poland, Sweden, Norway and the USA. What is more, a global partner network ensures local support all over the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Press and Public Relations

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: Johanna.Kiesel@aucotec.com

![]()