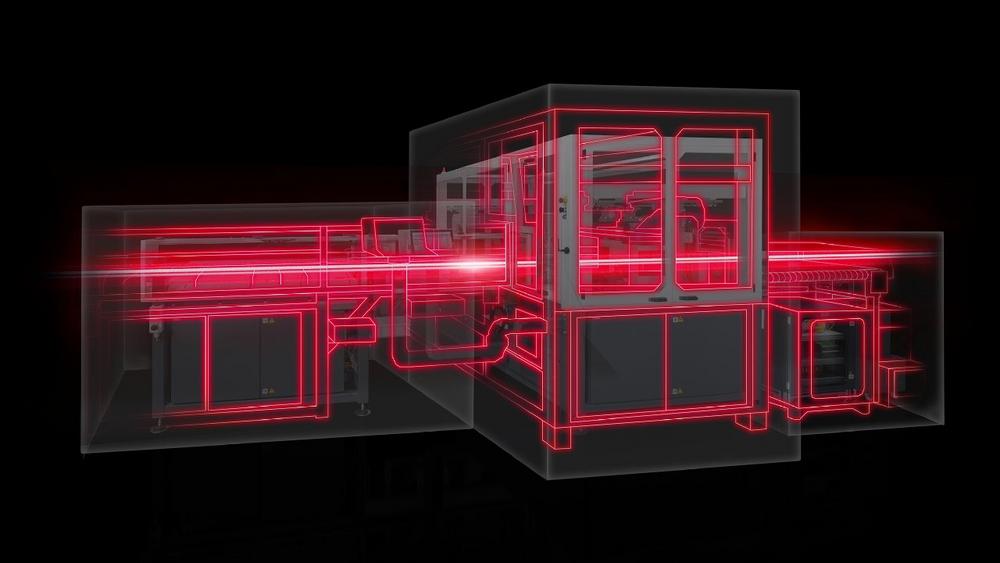

The key questions companies are asking themselves include: How do we manage to optimise engineering and downstream processes in a future-oriented way? How can we significantly increase our company’s order throughput? These aren’t easy questions to answer when the conditions in machine building and plant system engineering are characterised by supply bottlenecks, a shortage of skilled workers, and increasing customisation. Automation can improve processes and increase order throughput times. Eplan Head of Business Development Achim Potthoff explains: “Today, it’s not about ‘if’ to automate but ‘how’ to do it. It can be implemented based on modularisation and standardisation – in many cases using the Eplan eBuild and Eplan Engineering Configuration (EEC) solutions.”

Deep insights into how companies are achieving it

Experts from around the world will be comparing notes and exchanging ideas at the EF|A – Eplan Forum for Automated Engineering in September. This hybrid event offers attendees the space to network with experts from around the globe, live in Düsseldorf or online. This well-established forum includes lively reports on companies’ experiences with these practices – with live presentations from Andritz Digital Factory Ltd., Vortmann Steel Machinery, Arburg, Schmitt & Sohn, and Atlas Copco Airpower. There are also plenty of opportunities for networking during the two days of extensive exchange. In the “Meet & Match”, people can arrange in advance to meet during the event and network with one another in a “speed-dating” format.

Another special highlight is the participation of the VDMA, the German Association of Machinery and Equipment Manufacturers: Thomas Riegler will be taking registered participants on a tour through variant management.

From configuration to machine cabling

Presentations, Dive-In Sessions and Hands-On Sessions will provide valuable impulses for management and users alike – here are some excerpts from the range of topics being discussed:

- Siemens: Schematics configuration for Sivacon power distribution boards

- VDMA: Insights on the topic of variant management in mechanical engineering

- Arburg: Testing the digital cabling of machines

- Atlas Copco: Automated documentation in compressor manufacturing

- Schmitt & Sohn: Automated engineering in international elevator/lift construction

Exchaning practical experiences and ideas and networking with other decision-makers is one thing. Hands-On Sessions, during which users can experience the actual software, and Dive-In Areas on topics such as product structuring, standardisation or configuration are another. This allows practical questions to be answered directly onsite or online. Eplan partner companies including Configit, Encoway and SAE will also be represented with presentations on further strategic orientations and also their own virtual partner stands.

The event still has spaces available – click here to register:

EPLAN provides software and service solutions in the fields of electrical, automation and mechatronic engineering. The company develops one of the world’s leading design software solutions for machine and panel builders. EPLAN is also the ideal partner to streamline challenging engineering processes.

Both standardised as well as customised interfaces to ERP and PLM/PDM systems ensure data consistency along the whole value chain. Working with EPLAN means boundless communication across all engineering disciplines. No matter whether small or large enterprises: Customers can apply their expertise more efficiently. Worldwide, EPLAN supports more than 68,000 customers. EPLAN wants to grow further with customers and partners and pushes integration and automation in engineering forward. Within the EPLAN Partner Network, open interfaces and seamless integrations are realised together with partners. „Efficient engineering“ is the focus.

EPLAN was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The Friedhelm Loh Group operates worldwide with more than 12 production sites and over 95 international subsidiaries. The entire group employs more than 12.000 people and generated revenues of €3 billion in 2022. In 2023, the Friedhelm Loh Group was presented with the “Best Place to Learn” and “Employer of the Future” awards.

For more information visit:

www.eplan-software.com and www.friedhelm-loh-group.com

EPLAN GmbH & Co. KG

An der alten Ziegelei 2

40789 Monheim

Telefon: +49 (2173) 3964-0

Telefax: +49 (2173) 3964-25

http://www.eplan.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (2173) 3964-180

Fax: +49 (2173) 3964-163

E-Mail: hagelschuer.b@eplan.de

![]()