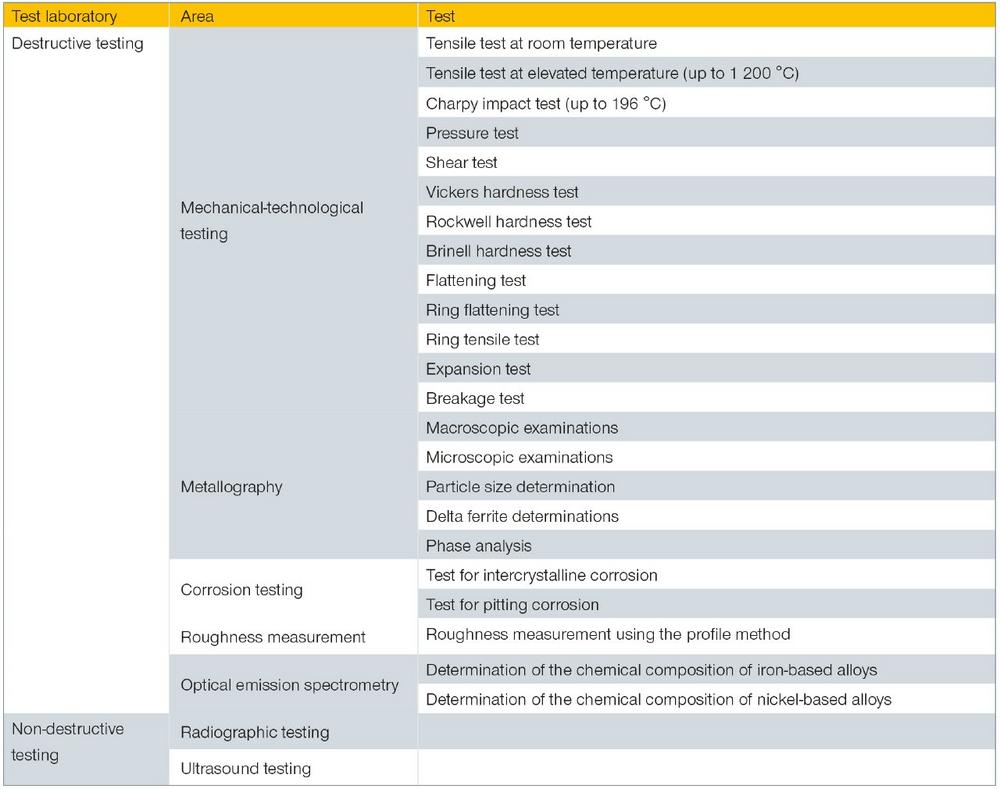

The German Accreditation Body (DAkkS) has authorised us to carry out the following testing:

- Mechanical-technological testing

- Mechanical testing

- Metallographic corrosion tests of metallic materials

- Material investigations of metals by means of optical spark emission spectrometry with steel and iron materials as well as nickel-based alloys

- Manual and mechanised non-destructive testing (radiographic and ultrasonic testing) of metallic materials, welded joints and steel pipes

In the past this authorisation was valid for a period of five years. In future the DAkkS will generally waive a time limit on the validity of the certificate in the case of re-accreditations. The basis for this is a ruling by the Federal Administrative Court in 2018, according to which accreditation decisions may be issued without a time limit.

The suitability of the test laboratory is continuously checked by the DAkkS through regular inspection audits (usually every 18 months).

The inspection criteria relate to work processes (technical audits) and documentation (system audits) as well as organisational measures. These audits round off the control process with regular internal audits and serve as proof of consistent competence. The basis for the internal audits is the quality management system with the Quality Management manual of the test laboratory according to DIN EN ISO/IEC 17025 as well as the Integrated Management System manual.

Flexible accreditation category III

In addition, BUTTING has recently been granted the flexible accreditation category III, which allows the test laboratory to freely select standardised test methods or test methods equivalent to them.

This category makes it possible to confirm on the annex to the accreditation certificate that the use of standardised or equivalent test methods and calibration guidelines with different revision levels is permitted. As an example, the testing standard, updated in 2021, for the performance of bending tests in accordance with DIN EN ISO 7438 can be cited here. This standard is annexed to the accreditation certificate with the issue date 2016-07, as this was the revision valid at the time the accreditation certificate was issued (September 2020). The automatic standards subscription allows BUTTING to use the test standard DIN EN ISO 7438 with the issue date 2021-03 without approval by the DAkkS.

Scanning electron microscope

There was great joy when the state-of-the-art scanning electron microscope (SEM) became operational last year.

The SEM is an indispensable inspection instrument in defect and damage analysis as well as quality assurance, and is used for both materials and components. Mathias Schlundt, Team Leader Laboratory, explains: “This major investment enables us to examine the microstructure with very high magnification and perform microanalyses. This has enabled us to further improve our inspection capabilities. On the one hand, we will use them to optimise products in the area of research and development. On the other hand, we can use our expertise to advise and support our customers and partners regarding quality issues.”

BUTTING – more than pipes – for a better quality of life

BUTTING Gruppe

Gifhorner Straße 59

29379 Knesebeck

Telefon: +49 (5834) 50-0

Telefax: +49 (5834) 50-320

http://www.butting.com

Marketing & Communications

Telefon: +49 (5834) 50-7091

E-Mail: Imke.Elbadaoui@butting.de

![]()