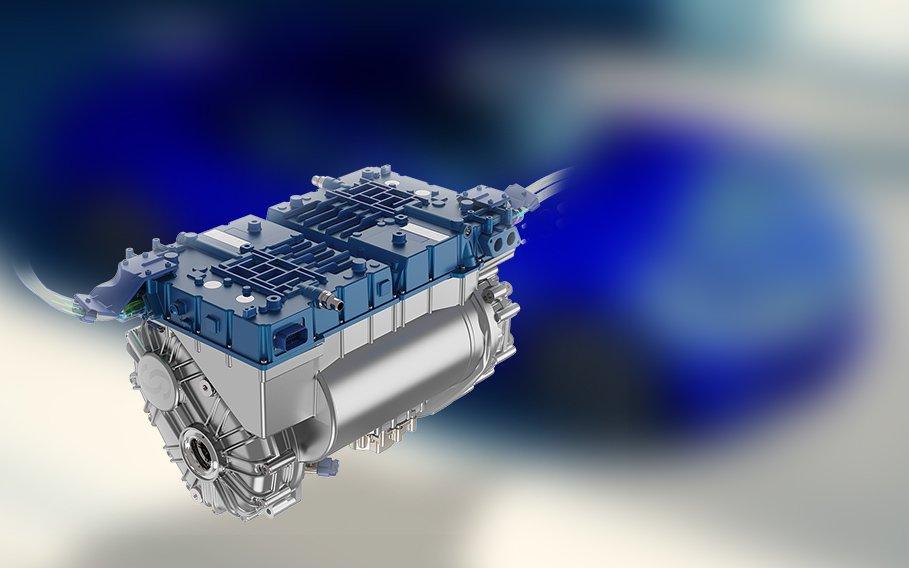

The new High-Compact Torque Vectoring EDU (HC TorVec EDU) consists of two combined EDUs, where each EDU can be controlled separately. Active torque vectoring enables better control of the power the car’s e-motors send to each wheel, allowing a more agile response to the different surfaces and driving conditions. Each wheel can, therefore, precisely accelerate and slow down independently, improving overall vehicle dynamics, handling, and stability by distributing additional torque in only fractions of a second. The improved reaction time and accurate response bring driving safety and feel to an entirely new level. In addition to the torque vectoring functionality, a clever combination of gears allowed the realization of this very compact design and a high-power density.

After introducing the previous High-Performance Torque-Vectoring e-axle from hofer powertrain in several high-performance sports cars, the engineers searched for new ways to optimize the successful architecture regarding power density and package. This goal was achieved using a new side-by-side architecture. In the architecture of the new HC TorVec EDU, the two powerful, modular, and scalable motors are arranged axis-parallel to each other and in axial prolongation to the side shafts. Besides the architectural changes, the electric axle’s performance has been raised to over 800 kW, consisting of 2 electric motors with more than 400 kW and a torque of 2 x 4500 Nm in the modular system. These performance levels are further extendable if required.

"This solution marks a new milestone in developing high-end compact powertrains without any loss in efficiency and functionality. It serves many application fields, being best suited for high-power or all-wheel drives." says the CTO, Wolfgang STEPHAN.

It can be used as dual engine torque vectoring primary drive unit or a single engine secondary axle in combination with other products of the ULTEVATE platform from hofer powertrain to realize the most advanced eDrives. One of the highlights is its compatibility with all new technologies, such as Form Litz winding in e-motors or HV booster.

hofer powertrain

Ohmstr. 15

72622 Nürtingen

Telefon: +49 (7022) 217884-0

Telefax: +49 (7022) 217884-129

http://www.hofer.de

Communication Specialist / PR

Telefon: +49 (176) 32647902

E-Mail: christina.karuna@hofer.de

![]()