The PROFIsafe interface of the servo drives makes an important contribution to the compact AGV drive system’s next-level safety architecture by reducing the complexity of the safety and control technology in the vehicles as well as the time and costs for commissioning and servicing. It also simplifies the configuration and documentation of the safety architecture. There are plans to implement more safe interfaces in the cyber® simco® drive 2 servo drive later in 2024.

Safe communication for AGVs, AMRs & co. enables cost-effective vehicle design

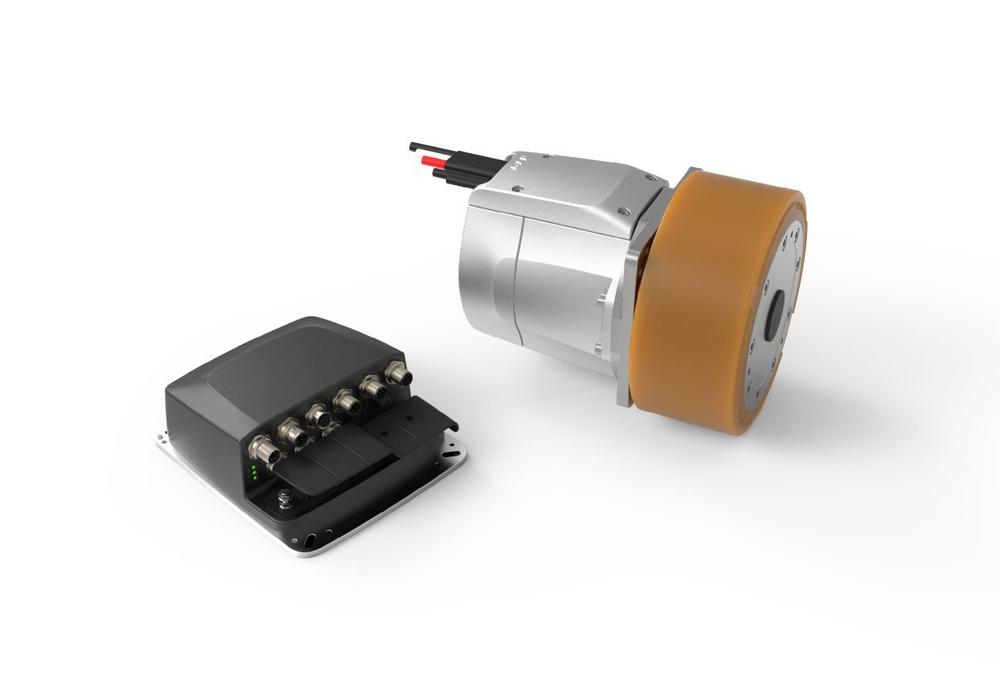

When equipped with an integrated safety board, the cyber® simco® drive 2 servo drive has a two-channel STO (Safe Torque Off) function even in the basic version. Safe Brake Control (SBC) and Safe Position (SP) safety functions as well as an emulation for the safety encoder in the wheel actuator can be optionally integrated.

Thanks to the PROFIsafe interface in the servo drive’s SIM2050 and SIM2100 output variants, manufacturers of AGVs and AMRs (autonomous mobile robots) can now design and implement their vehicle safety architecture even more easily and cost-effectively. The safe signals from the servo drive to the safety and vehicle control system are transmitted via a safety certified communication channel – eliminating the need for additional wiring or for a second channel for speed and position monitoring.

Overall, the safety certified cyber® simco® drive 2 PROFIsafe servo drive – and with it the cyber® iTAS® system 2 AGV drive system – meets SIL 2 and PL d requirements as stipulated by the majority of vehicle manufacturers and operators.

PROFIsafe interface supports next-level safety architecture

PROFIsafe is a standard for a communication protocol for the transmission of safety-relevant data via PROFINET or PROFIBUS in automation applications with functional safety. The technology – according to the PROFIBUS and PROFINET International Support Centre (PISC) in Karlsruhe, almost seven million nodes are meanwhile installed in the field – covers the entire communication path from the sensor to the controller and the actuator.

As a standard within IEC 61784-3-3, it integrates both safety and standard communication technology on one cable – ideally supporting the next-level safety architecture developed by WITTENSTEIN for the safety certified cyber® simco® drive 2 servo drive, as used in the cyber® iTAS® system 2, the compact drive system for AGVs. The safety architecture for AGVs, AMRs and other mobile platforms requires fewer cables and connectors, fewer interfaces, components and modules and reduces assembly and documentation effort – without in any way compromising safe AGV and AMR operation.

The WITTENSTEIN group at LogiMAT 2024

Frameless motors from WITTENSTEIN cyber motor enabling in-house development of actuators for AGVs and AMRs as well as small servo drive systems for auxiliary axes will be further highlights at the LogiMAT booth. WITTENSTEIN alpha will additionally be presenting planetary, bevel and worm gearboxes along with rack-and-pinion applications for material handling, among others.

For more information on the cyber® iTAS® system 2 drive system, go to: https://www.wittenstein-itas.com/…

With around 2900 employees worldwide and sales of €519 million in 2022/23, WITTENSTEIN SE enjoys an impeccable reputation for innovation, precision and excellence in the field of cybertronic motion – not just in Germany but internationally. The group possesses exceptional expertise for the mastery and further development of all technologies relevant to mechatronic drives and comprises six innovative Strategic Business Divisions. We develop, produce and sell products such as high-precision servo drives and linear systems, servo systems and motors as well as cybertronic drive systems for many areas of application including machine and plant construction, aerospace or oil and gas exploration. Nanotechnology and software components round off the portfolio. With 25 sites in more than 45 countries, the WITTENSTEIN group (www.wittenstein.de) is represented in all major technology and sales markets.

WITTENSTEIN SE

Walter-Wittenstein-Straße 1

97999 Igersheim

Telefon: +49 (7931) 493-0

Telefax: +49 (7931) 493-200

http://www.wittenstein.de

Leiterin Presse und Öffentlichkeitsarbeit/Pressesprecherin

Telefon: +49 (7931) 493-10399

Fax: +49 (7931) 493-10301

E-Mail: sabine.maier@wittenstein.de

![]()