„In future, the certification mark will supplement the existing draft certification marks „Ecodesign“, „Standby Power“ and „Energy“. In addition to consumer electronics, household, audio, video and power supply devices, electrical toys and sports and leisure products, we can now also comprehensively certify the sustainability of lighting products,“ says Florian Hockel, Segment Manager for Lighting, Luminaires and Multimedia Devices at TÜV SÜD. The new certification mark is based on the EU’s ErP Directive, which is part of the Ecodesign Directive. Both set requirements for the design of products with particularly low energy consumption.

Ecological aspects in the spotlight

The ErP Directive attaches great importance to product information. Manufacturers and importers in the EU are responsible for providing their lighting products with product information sheets, technical documentation and labelling. The latter is based on energy efficiency classes, ranging from A+++ for very energy-efficient products to G for very inefficient products. This information must be recorded in the European Product Database EPREL. For products with outdated labelling, the ErP Directive specifies transitional periods during which they must be provided with the newly scaled labels A-G.

"The product’s energy consumption, service life and light output must also be labelled. The information helps consumers to make sustainable purchasing decisions," says Florian Hockel. The directive sets limit values, for example for the power consumption of LED lamps in standby mode. If a product exceeds these limits, it may not be sold in the EU. Further requirements are set for service life, luminous flux in lumens and colour rendering. Procedures are listed for dealing with non-compliant products.

The ErP Directive applies to all lamps and luminaires that are suitable for use in households, commercial buildings and public areas. The requirements are set out in so-called implementing measures, which are organised by product group, for example office lighting or directional light sources. „This allows manufacturers to prove that their specific product and its main application fulfils all legal requirements,“ says Florian Hockel. This is becoming increasingly important for the external perception of companies and ensures competitive advantages. Consumers, in turn, receive a durable product that saves money on energy consumption.

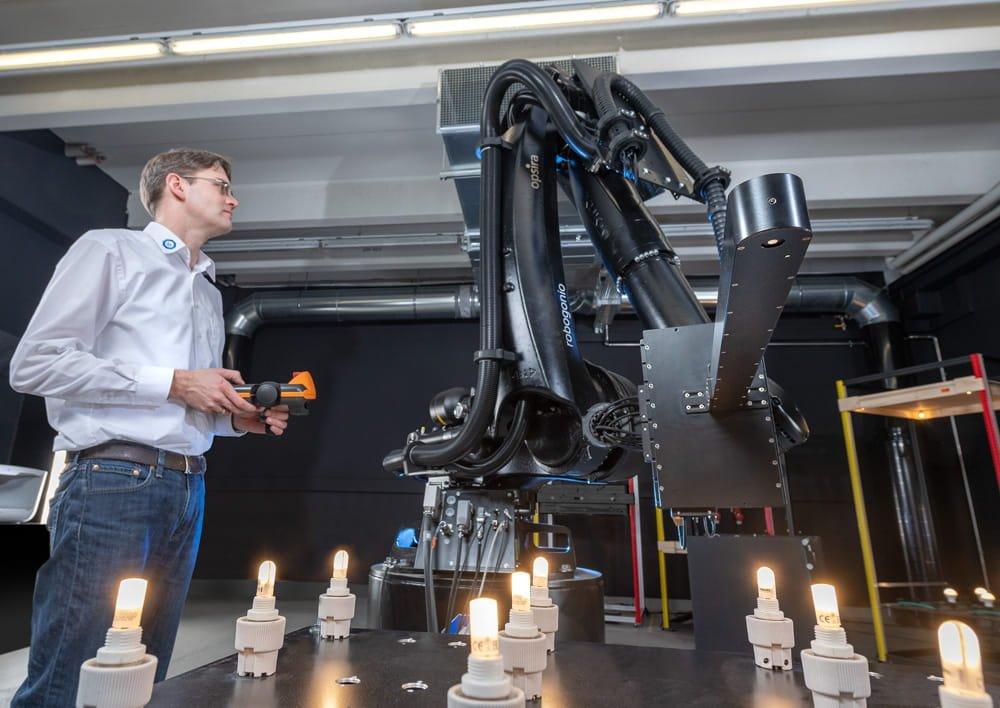

Hard-working helper improves test procedure

An ErP test is extensive. That’s why Florian Hockel is delighted to receive active support from his programmed colleague – the Robogoniometer. The robot with integrated light measurement technology determines the energy consumption of lamps and light sources. It carries out complex light measurements in endurance tests on LED lamps and uses the data to determine their service life – around the clock over a period of five months.

The Robogoniometer scans the light points and measures with two sensors that can be positioned as required. „This makes it extremely precise and the measurements repeatable. And it practically works on its own,“ emphasises Florian Hockel. Its automatic range control adjusts the measuring times to the frequency of the respective light source. This allows TÜV SÜD to test a wide range of applications, such as surgical lights that require a homogeneous, spectral light distribution. This is why the machine is equipped with a spectroradiometer in addition to a photometer unit for measuring light intensity. It records the intensity and wavelength of the entire spectrum. „All measurement data is analysed in the shortest possible time and collected in a database,“ says Florian Hockel. „The manufacturer can access it at any time during the project and use it as a basis for further product development. Thanks to the Robogoniometer, we are now realising up to 300 projects simultaneously at over 8000 light points.“

Professional product tests in accordance with the Ecodesign Directive

The less power an electronic product needs to do its job, the more energy-efficient it is. TÜV SÜD tests electronic products in accordance with the Ecodesign Directive, among others. It includes requirements for energy-using products (EuP) on the one hand and specifications for energy-related products (ErP) on the other. The latter are passive products such as cables, which can nevertheless have an impact on energy efficiency.

TÜV SÜD’s experts test a large number of products that fall under the Ecodesign Directive (ErP Directive). These are products or product groups that have a significant impact on the environment and show a high potential for improving environmental compatibility. These include, for example, office equipment such as PCs and monitors, household appliances, consumer electronics, printers, copiers and multifunctional devices as well as air conditioning units.

When testing in accordance with the Ecodesign Directive, TÜV SÜD tests, for example, power consumption in off and standby mode, the availability of standby or idle functions and minimisation of consumption. Voluntary tests usually include the determination of energy consumption.

Further information: www.tuvsud.com/erp-directive

Founded in 1866 as a steam boiler inspection association, the TÜV SÜD Group has evolved into a global enterprise. More than 26,000 employees work at over 1.000 locations in about 50 countries to continually improve technology, systems and expertise. They contribute significantly to making technical innovations such as Industry 4.0, autonomous driving and renewable energy

TÜV SÜD Customer Engagement and People GmbH

Westendstraße 199

80686 München

Telefon: +49 (89) 5791-0

Telefax: +49 (89) 5791-1551

http://www.tuvsud.com/de

Unternehmenskommunikation / Corporate Communications

Telefon: +49 (89) 5791-1592

Fax: +49 (89) 5791-2269

E-Mail: Dirk.Moser-Delarami@tuev-sued.de

![]()