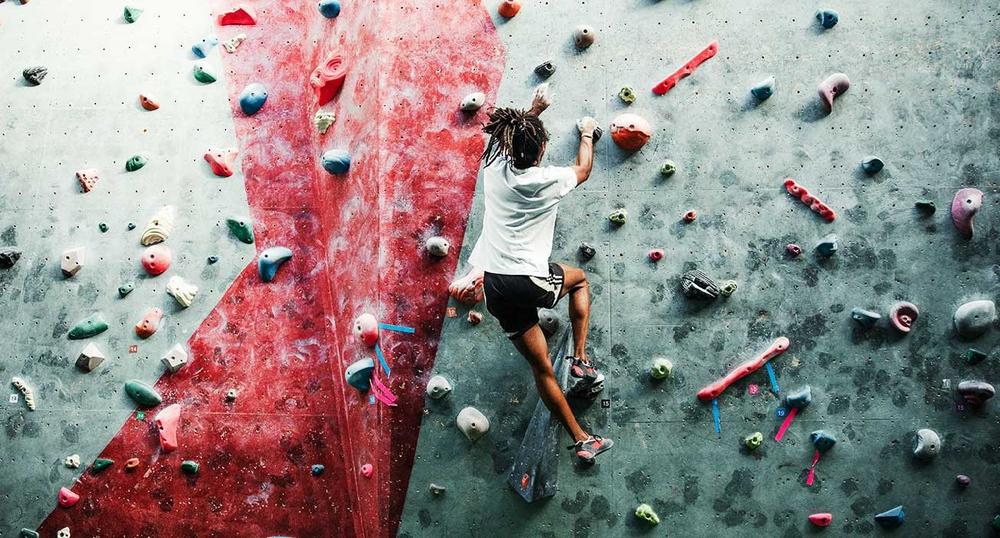

RAKU® TOOL IE-3092 is the ideal choice for climbing hold production as it enables customers to create their own grips easily and efficiently without having to outsource to a manufacturer.

The polyurethane system is easy to process both by hand-batching and automated meter-mix processes. It is poured into a silicone mold and then cured in an oven.

The low-viscosity liquid casting compound features

- Excellent abrasion and impact resistance

- Very fine surface structure

- High molding accuracy

- Long pot life

RAKU® TOOL IE-3092 can be ordered in quantities from quart kits to 275-gallon totes in order to accommodate production volumes from home-wall user to high output manufacturing, and anything in between.

RAMPF Group, Inc. also carries an extensive line of pigments, mold releases, and molding silicone rubber needed to satisfy all requirements for creating molds and casting holds.

Engineering. Chemical. Service.

Your partner for reactive resin systems, machine systems, and lightweight construction with composites.

– Production and recycling of materials for modeling, lightweight construction, bonding, and protection

– Comprehensive range of solutions and services, particularly for innovative customer-specific requirements

– Technical production systems for precise, dynamic positioning and automation, as well as technologies for complex composite parts production

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

http://www.rampf-group.com

Pressereferent

Telefon: +49 (7123) 9342-0

E-Mail: pr@rampf-group.com

![]()