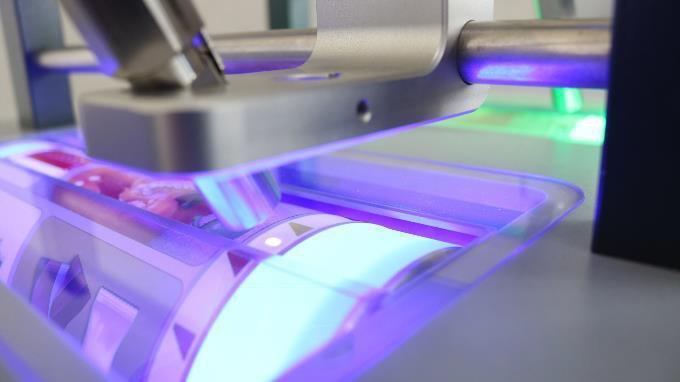

TWINStar is a register control system that can be used universally. It is suitable for printing houses that want to operate their presses efficiently, as well as for manufacturers of presses and tool stations, that want to offer systems with optimally controllable process sequences. TWINStar demonstrates its strengths particularly in the control of postpress printing units, in finishing or tool stations and in the insetting of preprinted materials: The TWINStar’s adaptive RSH fiber optic register mark sensor is able to reliably detect even extremely low-contrast and metallized inks, as well as transparent coatings. The system thus ensures optimum production results and waste is effectively reduced. TWINStar uses the proven, high-performance control algorithms of the regi_star 20 for this purpose. With its fully automatic scanning technology, it supports both the flexible eltromat single-head and standard two-head measuring processes.

Due to its modular design, the system is very flexible and can be used for many applications. Even in its basic version, TWINStar comes with a wide range of intelligent functions for effective register control, such as RegiChart: the register trend display clearly visualizes the register progress of the control points over time or distance during printing. TWINStar ensures high-quality production by utilizing the various web and web-cylinder measuring techniques in any combination, as well as highly dynamic control cores that are specifically optimized for the application.

Simple operation: "One View. One Click."

"With the maxim "One View. One Click", the operation of TWINStar follows the demand for maximum reaction speed and intuitive simplicity. The system supports the operator and makes his work easier. With all important information always in view, he can reach all necessary functions with just one click thanks to the modern touchscreen user interface," says Dieter Jochmann, Product Manager at BST. On the compact 10.1 inch display, the operator sees the captured register marks together with the scanned mark signal as a color live image. This allows him to reliably assign even hard-to-see marks. If register deviations threaten to exceed specified tolerances, or if other problematic conditions occur in the processes, the system alerts the operator in good time with corresponding graphic symbols so that he can take immediate countermeasures during ongoing production and effectively prevent waste.

Simple integration into different systems TWINStar has a flexible system architecture that allows it to be used on both new and existing machines for retrofitting. Via the Profinet integration interface, the system can be integrated directly into the machine environment to interact with it and provide all process-relevant data. This data can then be used to achieve maximum process reliability and maximum quality. TWINStar boosts productivity by providing first-class performance and quick setup.

Über BST

Die BST GmbH, eine Gesellschaft der elexis Unternehmensgruppe, gehört zu den führenden Anbietern von qualitätssichernden Systemen für bahnverarbeitende Industrien. Das Unternehmen mit Sitz in Bielefeld bietet Lösungen für Bahnlaufregelung, Oberflächeninspektion, Bahnbeobachtung, 100%-Inspektion, Farbmessung, Farbmanagement, Registerregelung sowie Automatisierung an. In diesen Bereichen verfügt das Unternehmen über jahrzehntelanges Praxis-Know-how mit Installationen bei weltweit mehr als 15.000 Kunden aus den Industrien Druck- und Verpackung, Papier und Folien, Gummi- und Reifen, Batterie und Brennstoffzellen, sowie gedruckter und organischer Elektronik. BST steht für hochwertige Qualitätsüberwachung, reibungslose Produktionsprozesse und erstklassigen Service weltweit.

elexis AG

Industriestr. 1

57482 Wenden

Telefon: +49 (2762) 612-130

Telefax: +49 (2762) 612-135

http://www.elexis.group

Head of Corporate Communications

Telefon: +492762612286

E-Mail: Konrad.huenerfeld@elexis.de

![]()