"Battery enclosures are a key component in electric vehicles. In various collaborative projects, AZL is holistically investigating the challenging requirements and developing concepts on how plastic-based multi-material solutions can save weight and costs compared to status quo metal solutions." Peter Dill, Director Product Portfolio Global at Röchling Automotive, is among the partners that AZL GmbH brings together across all value chains and material categories. "Working together in the consortium allows us to exchange creative ideas and brings new impulses, such as on the possibilities of new materials in terms of crash and fire protection. We at Röchling Automotive are already looking forward to the next project, which this time will focus on cell-to-pack housings," Dill added.

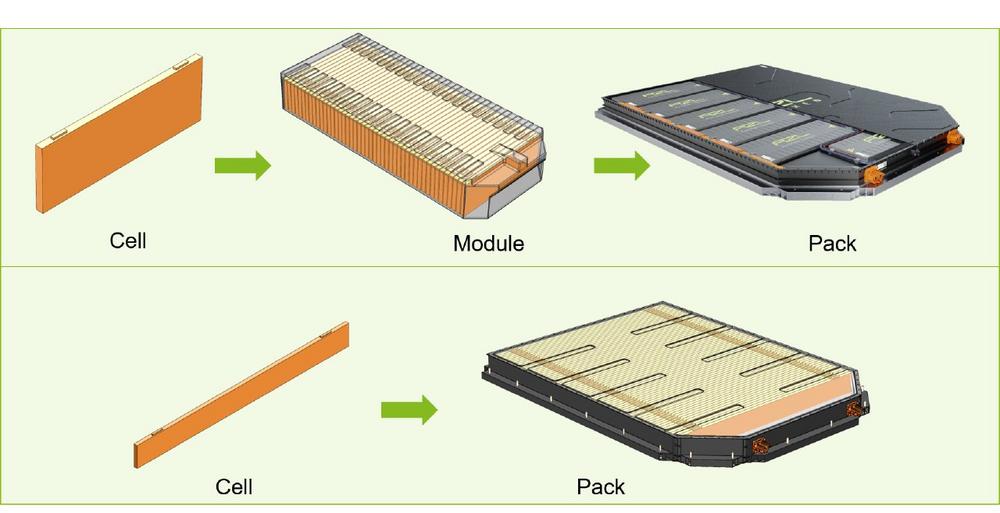

The design of battery housings is crucial for safety, capacity, performance, and economics. The Cell-to-Pack project, which is starting now, will focus on developing concepts for structural components and for producing them based on a variety of materials and design approaches. The concepts will be compared in terms of performance, weight and production costs, creating new know-how for OEMs, producers and their suppliers throughout the battery vehicle value chain. Companies are now invited to participate in this new cross-industry project to develop battery enclosure concepts for the promising and trend-setting cell-to-pack technology.

The basis for the project is the lightweight engineering expertise of the AZL experts, which they have already demonstrated in previous projects for multi-material solutions for module-based battery housings. Together with 46 industry partners, including Audi, Asahi Kasei, Covestro, DSM, EconCore, Faurecia, Hutchinson, Johns Manville, Magna, Marelli and Teijin, 20 different multi-material concepts were optimized in terms of weight and cost and compared with a reference component made from aluminum. All production steps were modelled in detail to obtain reliable cost estimates for each variant. Result: depending on the concept, 20% weight or 36% cost savings potential could be identified by using multi-material composites compared to the established aluminum reference. "In the joint project, the challenging requirements were comprehensively investigated by the AZL and concepts were developed on how plastic-based multi-material solutions can save weight and costs compared to status quo solutions made of metals. We are also looking forward to impulses for the implementation of plastic battery housings for cell-to-pack technology and the cooperation in the follow-up project." says Dr.-Ing. Florian Meyer, project management mentor on the part of Audi AG’s Technical Development.

It is expected that the design concept of battery enclosures will develop in the direction of a more efficient layout. In this case, the cells are no longer combined in modules in additional production steps, but are integrated directly into the battery housing. The elimination of battery modules and the improved, weight-saving use of space will allow for higher packing density, reduced overall height and cost saving. In addition, various levels of structural integration of the battery housing into the body structure are expected. These new designs bring specific challenges, including ensuring protection of the battery cells from external damage and fire protection. In addition, different recyclability and repair requirements may significantly impact future designs. How the different material and structural options for future generations of battery enclosures for the cell-to-pack technology might look like and how they compare in terms of cost and environmental impact will be investigated in the new AZL project. In addition to the material and production concepts from the concept study for module-based battery enclosures, results from a currently ongoing benchmarking of different materials for the impact protection plate and a new method for determining mechanical properties during a fire test will also be incorporated.

The project will start on October 27, 2022 with a kick-off meeting of the consortium, interested companies can still apply for participation until then.

AZL stands for excellence in lightweight production. As one-stop shop for market and technology know-how, the senior staff of AZL supports companies of the entire value chain, in the development, benchmarking and improvement of design methodologies, manufacturing techniques and products. Located in the heart of one of the leading high-tech ecosystems, RWTH Aachen University, AZL assist in experimental evaluation of all relevant technologies related to composite-based multi-material technologies with decades of technology expertise and cutting-edge infrastructure. In addition to individual cooperation, the AZL Partnership framework offer access to services and a network of 80+ international companies along the lightweight value chain. With three pillars advisory, engineering and partnership network, the AZL develops competitive innovations for economically highly relevant market segments and finds suitable partners for industrial implementation and establishment in the market.

www.azl-lightweight-production.com

AZL Aachen GmbH

Campus Boulevard 30

52074 Aachen

Telefon: +49 (241) 475735-0

Telefax: +49 (241) 475735-18

https://azl-aachen-gmbh.de

Senior Project Manager

Telefon: +49 (241) 475735-14

E-Mail: philipp.froehlig@azl-aachen-gmbh.de

Design Leader

Telefon: +49 (241) 475735-17

E-Mail: warden.schijve@azl-aachen-gmbh.de

![]()