A key component of the MDR relates to permanently legible labeling for medical devices (Unique Device Identification, UDI). The purpose of the traceable UDI code is to enable rapid product recalls within the supply chain – the corresponding information is stored in the European Database for Medical Devices (EUDAMED). Reusable surgical instruments, which may be subjected to repeated autoclave cycles depending on the area of application, represent a major challenge with regard to “permanently legible labeling”.

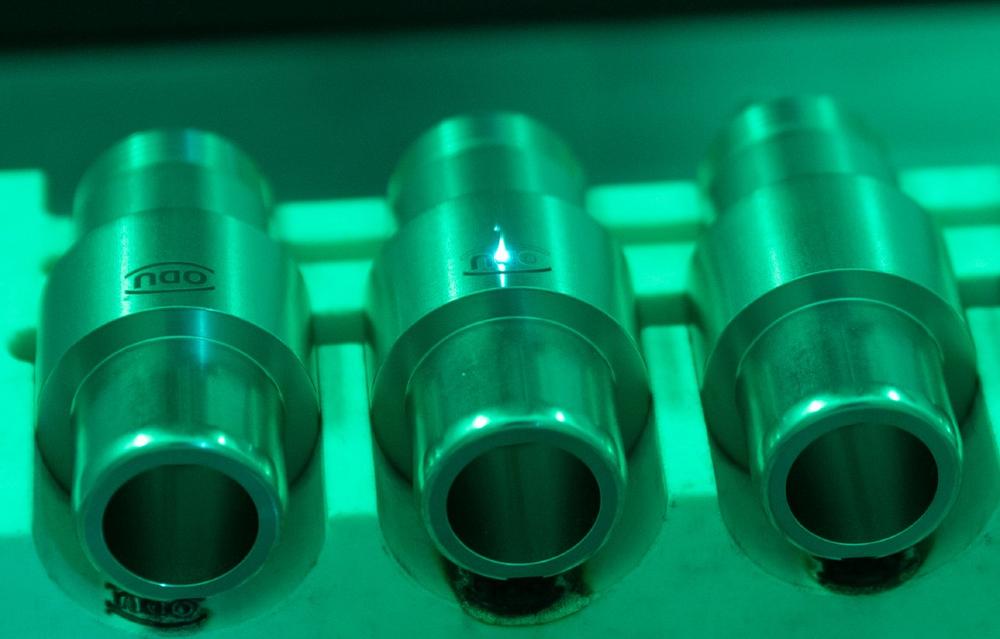

As a supplier of connectors, assemblies, as well as units for medical technology, ODU supports its customers with laser marking in accordance with the UDI. During what is known as “cold processing”, the ODU connectors (both metal and plastic) are structured using an ultra-short-pulse fiber laser without being subjected to thermal or mechanical influences.

Since the surface structure remains unchanged, the product can be kept clean and sterile. The markings remain permanently legible thanks to their corrosion resistance, stable viewing angle, as well as their structure – even after the specified maximum number of autoclave cycles. The laser markings are also resistant to acids, cleaning agents, and bodily fluids.

“We can implement Unique Device Identification (UDI) by laser marking our plugs. “Furthermore, at ODU we focus on product-related topics, such as patient and user protection, and implement them in compliance with IEC60601-1,” says Mathias Wuttke – Business Development Manager for the Medical Technology division.

In a complex process, the area in which the wires enter the connector can then be molded with silicone, resulting in a perfectly sealed yet flexible connection. The silicone overmolding does not peel off or become detached even after the required number of autoclaving cycles (steam sterilization at up to 134°C and 3,040 mbar) – its biocompatibility relating to cytotoxicity testing (outgassing) in accordance with DIN EN ISO 10993-5 is confirmed by an external testing laboratory.

Satisfied customers and the high quality of our products are the primary focus for ODU. In order to ensure success in the market in compliance with the law, we support our customers in the following areas:

- End-to-end risk and change management

- Seamless traceability of materials and productions

- Consideration of the requirements in the supply chain

- Reporting requirements for CMR substances

- Extended retention periods for documentation

The ODU Group is one of the world’s leading suppliers of connector systems, employing 2,500 people around the world. In addition to its company headquarters in Muehldorf a. Inn (Germany), ODU also has an international distribution network, production and product development sites in Sibiu/Romania, Shanghai/China, Tijuana/Mexico and Camarillo/USA. ODU combines all relevant areas of expertise and key technologies including design and development, machine tooling and special machine construction, injection, stamping, turning, surface technology, assembly and cable assembly. The ODU Group sells its products globally through its sales offices in China, Denmark, France, Germany, Hong Kong, Italy, Japan, Korea, Romania, Sweden, UK and the US, as well as through numerous international sales partners. ODU connectors ensure a reliable transmission of power, signals, data and media for a variety of demanding applications including medical technology, military and security, automotive, industrial electronics, and test and measurement.

ODU GmbH & Co. KG

Pregelstraße 11

84453 Mühldorf a. Inn

Telefon: +49 (8631) 6156-0

http://odu-connectors.com/de/

Produkt Marketing Spezialistin

E-Mail: tanja.stilkerich@odu.de

![]()