For some applications, the SIL2/PLd safety level is not sufficient. For example, autonomous vehicles, so-called AGVs (Automated Guided Vehicles), which move independently and computer-controlled in public areas. Since the safety requirements are particularly high here – high personal injury and property damage can occur if the vehicle functions incorrectly – a high safety level is required for the technology used. The vehicles must be equipped with SIL3 components, sometimes on the wheels, to detect steering angle and speed. Remote-controlled vehicles that are moved without a driver present should also be mentioned. They are steered remotely from a workstation. With his seat equipped with monitors, pedals and steering wheel, the operator can remotely steer a vehicle equipped with cameras and remote technology to the desired destination. And back again, of course. Fast internet according to the 5G standard is provided for transmission to the vehicle.

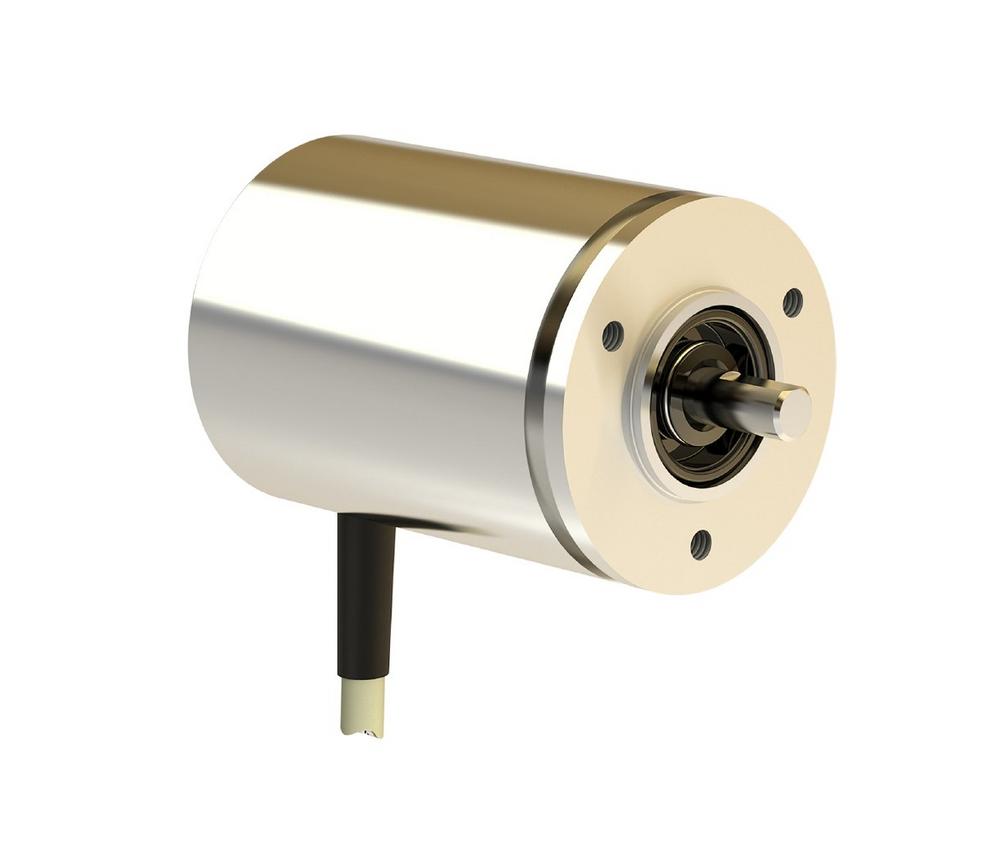

TWK offers SIL3 encoders for the control elements of the remote steering station to record the important control commands. The first devices of the TxSN model will be delivered at the end of 2022. The fully redundant design and advanced diagnostic and watchdog functions ensure SIL3 capability. In addition, extensive test procedures for hardware and firmware during the design phase and later for each device to be delivered in production are prerequisites for certification according to IEC 61508 with level SIL3 and ASIL-D conformity according to ISO 26262. Each encoder then outputs the position value, which is recorded twice, checked for plausibility and processed in separate microcontrollers, via the SIL3-capable bus system and the CANopen safety protocol. Normal and bit-inverted. The usual safety check then takes place in the safety control, whether both values arrive within a time window and whether they are identical – except for the inversion. If this is not the case, an alarm is triggered and the vehicle is stopped.

For this model, as well as for the already established SIL2 / PLd models, some features for further applications are planned, which facilitate the design of the customer application. For example, a wide range of robust enclosures is available: seawater-resistant aluminium as standard, various stainless steels – including food-grade, magnetically shielding stainless steel for applications with strong magnetic fields, or special enclosures for versions for explosion protection according to ATEX Zone 1 and 21. The most compact version is the one with a housing diameter of only 42 mm.

Other features of the TxSN: position resolutions up to 16 bits, parameterisable gate time for speed measurement, speeds up to 10,000 rpm and many flange and shaft forms. Protection classes up to IP69K are possible as well as a shaft load capacity up to 250 N axial and radial. The electrical connection is realised via M12 plug or cable.

Further information can be found at: www.twk.de

TWK-ELEKTRONIK GmbH

Bismarckstraße 108

40210 Düsseldorf

Telefon: +49 (211) 96117-0

Telefax: +49 (211) 637705

http://www.twk.de

Marketing

Telefon: +49 (211) 96117-0

E-Mail: info@twk.de

![]()