Excellent lens quality offering a combination of attractive style and perfect vision is a prerequisite for providing eyewear to consumers. Since the 2000s, MEI System has transformed the production processes used in the optics sector, over time emerging as the dominant force in the lens cutter industry. It was indeed MEI System that introduced the milling process for lens edging to the optical arena, overturning the old concept of grinding. The new process developed and perfected by the Bergamo-based company has significantly improved the flexibility and output of lens production lines, allowing manufacturers and optical laboratories to cut with extreme precision and quality, even in the most complex shapes required by the increasingly demanding eyewear market.

Innovation drives productivity

Daniel Ponti, Global Operations Director of MEI System, says: "Our company has always aimed to be the market’s technological leader, with a strong capacity for innovation driven by constant investment in research and development. We’ve introduced many new concepts in the more than 20 years of serving the optics industry, all intended to guarantee quality by minimising waste during the lens manufacturing process and meeting the specific needs of each customer. It’s a process that continues to this day and one that’s allowed us to expand our scope of operations on a constant basis. Today, we no longer only supply machines with the optimal technology for cutting lenses, but also integrated solutions for quality control, flow analysis within customer production lines, and multiple automation and optimisation solutions. These offerings deliver concrete advantages to the different customer types we serve, from the world’s biggest lens manufacturers and large independent laboratories, to local labs and individual shops that produce spectacles ondemand ready for quick delivery to the consumer.”

Making complex processes simple and being the first to find a solution to the increasingly complex demands of the optical world has been MEI System’s guiding philosophy over the years. For example, among its renowned inventions is the ‘No Block’ system for locking lenses during machining, which has completely eliminated the need to use consumables (the so-called ́blocks). The end result is considerable streamlining of the manufacturing process, with significant savings in resources, time and costs.

Leading components from leading suppliers

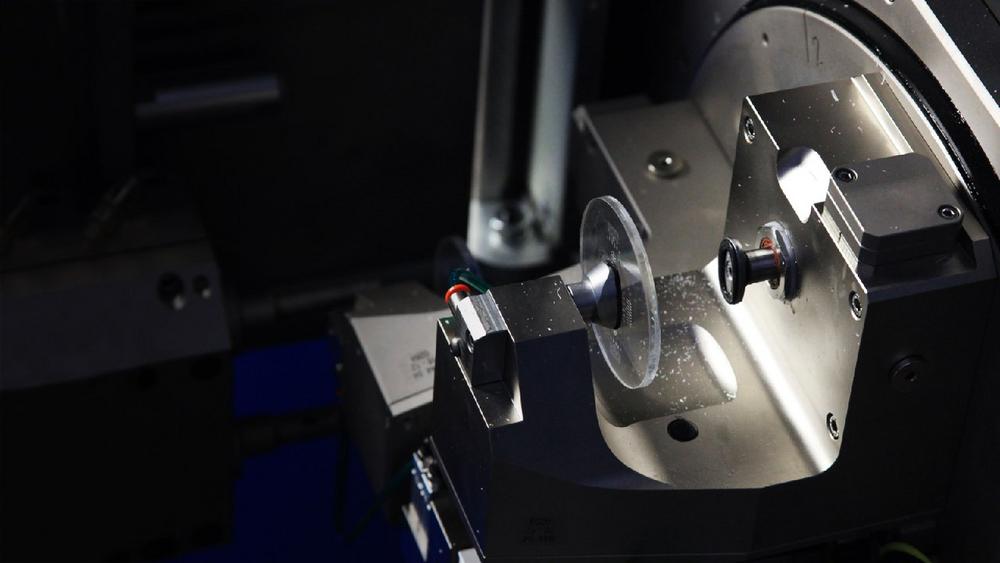

To position itself as a technological leader in the company’s reference market, MEI System manufactures its machines in-house, using leading suppliers for all the main components, including NSK for the ball screws. An essential element to guarantee extreme precision and fluidity of movement, NSK ball screws make the machines capable of performing top-quality milling on the various materials used to make lenses today.

"Our technical department recognises the NSK brand as a reference point for linear motion components, and our long-standing relationship testifies to the absolute quality of the products offered by the Japanese multinational,” says Mr Ponti. “However, even more important is the relationship of trust and partnership established between the two companies, which goes far beyond technical excellence. With NSK we have framework stock management agreements that allow us to align our requirements through monthly rolling forecasts, so that our supply chain is not subject to delays or interruptions, but is not oversized either. The end result is excellent and mutually beneficial, giving us certainty that materials will be available on time with optimised financial commitment."

Towards new markets

The great success of the technological solutions introduced by MEI System has provided further impetus to the internationalisation of the company and the development of new solutions for new segments within the optics market.

MEI System, which already has subsidiaries in the United States, Hong Kong and Brazil, has extended its global presence by opening offices in the United States, India, Japan and Australia. This strategy is allowing the company to get even closer to its global clientele and take advantage of new development opportunities.

On a technological level, the focus on research and development continues, leading to the creation of a new generation of machines for the construction ophthalmic lens market. The company’s solutions promise to revolutionise this type of processing, where the milling operation is used not only to define the contour, but also the surface of the lens, thus providing the correct customised shape according to the specification required by the consumer.

"In the case of construction ophthalmic lenses,” explains Mr Ponti, “the milling quality and precision requirements are even more extreme, with very tight tolerances, as even the slightest imperfection in shape would negatively affect the quality of vision. For these projects our engineers also use NSK ball screws to transform rotary motion into rectilinear movement, ensuring maximum positioning accuracy."

It is another example of how a strong partnership between two technology leaders in their respective fields fosters growth and the development of innovative solutions that can break into new markets.

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 30,400 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2020, the more than 4,350 employees of NSK Europe Ltd. generated sales of over € 792 million.

www.nskeurope.com

NSK Deutschland GmbH

Harkortstrasse 15

40880 Ratingen

Telefon: +49 (2102) 4810

http://www.nskeurope.de

Telefon: +49 (2102) 481-2152

E-Mail: albayrak-s@nsk.com

Telefon: +34 (600) 780-385

E-Mail: k.matsuo@mepax.com

![]()