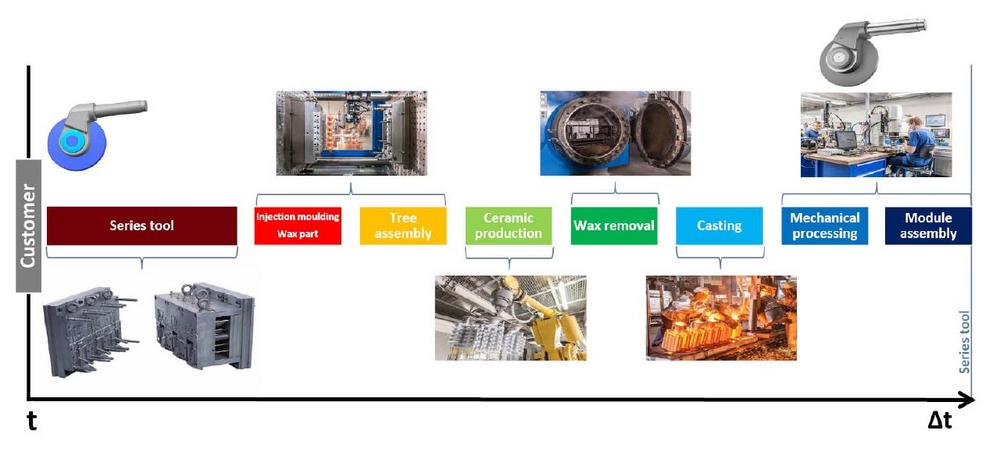

The process

At the beginning, a tool is needed which is used to produce the wax parts. The wax parts are almost identical to the later casting part regarding the dimensions. Slight deviations are due to different shrinkages of industrial wax and the metal alloy used. The wax parts are then glued together to form trees, which means that from now on several individual parts can be produced in a single manufacturing step. The casting shell is then formed by dipping the wax trees in ceramic mass and then sprinkling them with sands of different grain sizes. After drying, the wax is evaporated and the shell, formed this way, is burnt at over 1000 °C. This is followed by the casting of the hot metal: the investment casting. When the shell has cooled down completely, it is knocked off and the parts are separated from the casting tree, cleaned and further processed.

Hybrid casting

"The idea of BLANK hybrid casting is now to replace the production of the wax part using an injection mold with wax 3D printing," says Bühler, "On the one hand, this shortens the production time considerably, on the other hand, also part geometries can be realized that were previously impossible or very difficult to produce using investment casting."

This can be seen, for example, in the production of acetabular cups. The casting part consists of a solid shell-shaped head, on the surface of which are hundreds of small so-called tripods. These fine, cross-shaped anchors are the link between the implant and the bone. Initially, the tripods were glued to the cup by hand in the wax part, which was extremely time-consuming and very filigree manual work, making each implant a unique piece. Within the project implementation a realization in wax 3D printing could be achieved thanks to the BLANK hybrid casting, allowing a positioning of the tripods accurate to a tenth of a millimeter. Impossible by hand! This ensures a more secure mechanical connection between the tripods and the femoral head, procures continuity to the process and enables a reduction in throughput and personnel costs.

Another application example can be found in racing. In this sector, weight reduction plays a decisive role in order to be faster and more agile. As part of a manufacturing cooperation, a bionic wheel carrier construction was developed which, despite considerable weight saving, can withstand the required loads of the end application. Compared to the original milled part, over 40 percent of the weight was saved. This bionic part construction can only be produced in this form using BLANK hybrid casting.

The explained reduction in production time through 3D printing pays off especially for prototypes or small series. "Depending on customer requirements, the investment casting process consists of 20 to 60 individual operations. This may involve a high throughput time and sacrifice flexibility. Here hybrid casting can be an interesting alternative to the regular manufacturing process, especially for small batches or spare parts procurement," says Bühler. For a fully comprehensive smart concept, an online 3D printing calculator has also been integrated on FEINGUSS BLANK’s homepage. "This accelerates the ordering process for our customers and even enables production of investment castings within just 23 working days."

Link to the topic: https://www.feinguss-blank.de/en/company/news/detail/der-blank-hybridguss-smarte-effizienzsteigerung-durch-3d-druck

Link to the 3D printing online calculator: https://www.feinguss-blank.de/en/investment-casting/development-partner/prototyping

The BLANK-Group -Hidden Champion in the heart of Oberschwaben (Upper Swabia)

We are a family-owned business with about 1000 employees which has been successfully producing investment casting parts and exporting them all over the world for 60 years. Whether steel or aluminum investment castings – we are your partner for the realization of your investment casting idea.

The BLANK-Group, consisting of FEINGUSS and FORMENBAU BLANK GmbH, B² smart precision in Romania and FEINGUSS BLANK USA Inc., is one of the leading investment casting foundries with a machining center in Europe. No other metal-forming process can produce as complex and as cost-effective geometries as the lost wax investment casting process. FEINGUSS BLANK’s investment castings are easily distinguishable by the highest level of quality, down to the smallest level of detail, and an almost inexhaustible variety of materials. For six decades, we have been a premier partner in the automotive industry, mechanical and plant engineering, electrical engineering, precision mechanics, and many other industries.

Texmo Blank Germany GmbH

Industriestr. 18

88499 Riedlingen

Telefon: +49 (7371) 1820

http://www.TexmoBlank.com

Marketing & Unternehmenskommunikation

Telefon: +49 (7371) 182-200

Fax: +49 (7371) 18244-200

E-Mail: Manuela.Schmid@feinguss-blank.de

![]()