At PCIM, RAMPF Polymer Solutions will be presenting its wide-ranging portfolio of electro casting resins for the following power electronics applications:

- On-board chargers

- AC/DC converters

- DC/DC converters

- Power capacitors

- Relays

- EMC filters

The casting resin systems based on silicone (RAKU® SIL), polyurethane (RAKU® PUR), and epoxy (RAKU® POX) offer reliable and efficient protection against chemical substances and environmental influences such as heat, cold, and moisture. They also ensure optimum thermal management and excellent temperature resistance (thermal endurance).

Products for thermal management

- Silicone-based gap fillers with outstanding thermal conductivity of > 1.5 W/m K, low Shore hardness, good long-term thermal endurance, and thixotropic behavior that ensures excellent processability at very high dispensing speeds.

- Silicone-free gap fillers with a thermal conductivity of > 1.0 W/m K, a high level of elasticity, and good thixotropic properties.

- Silicone casting systems with high thermal conductivity of up to 1.7 W/m K, low Shore hardness, high long-term thermal endurance, and low mix viscosity.

Products for thermal endurance

- Polyurethane resins in thermal class B with heat resistance up to 130°C, flame retardancy to UL 94 V0, impressive thermal conductivity as high as 1.1 W/m K, and very good thermal shock resistance.

- Polyurethane resins in thermal class F with heat resistance up to 155°C, flame retardancy to UL 94 V0, and thermal conductivity of up to 1.5 W/m K.

- Epoxy resins in thermal class F with heat resistance up to 180°C, good thermal shock resistance, and excellent resistance to chemicals.

Material and processing from a single source

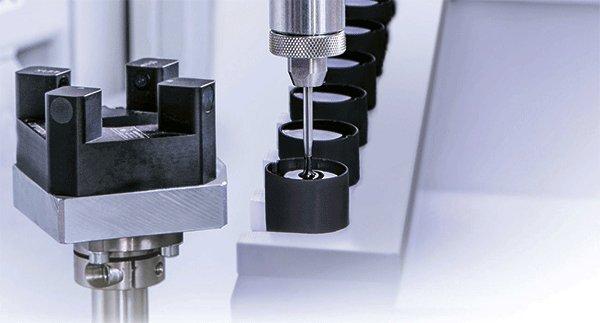

Material quality and processing are key to the correct functioning and durability of electrical/electronic systems. Mixing and dispensing systems from sister company RAMPF Production Systems ensure thermally conductive materials with a range of viscosities and densities are processed effectively and dispensed with pinpoint accuracy.

Project-specific automation concepts are also available, with integrated systems for component handling, control and sensor technology, image processing, and much more.

Visit RAMPF Polymer Solutions at at PCIM 2022 in Nuremberg from May 10 to 12 – Booth 455 / Hall 6!

RAMPF Polymer Solutions GmbH & Co. KG based in Grafenberg, Germany, is a leading developer and manufacturer of reactive resin systems based on polyurethane, epoxy, and silicone.

The product portfolio includes liquid and thixotropic sealing systems, electro and engineering casting resins, edge and filter casting resins, adhesive systems, and hotmelt adhesives.

The products of the RAKU® PUR (polyurethane), RAKU® POX (epoxy), RAKU® SIL (silicone), and RAKU® MELT (hotmelt adhesives) brands ensure the best solution for your application.

R&D is a top priority. In the RAMPF Innovation Center, experts work daily on the development of new products, the enhancement of existing products, and new material combinations.

RAMPF Polymer Solutions is certified to ISO 9001, IATF 16949, ISO 50001, and ISO 14001. The products are listed by leading manufacturers in the automotive, electrical, and electronics industries, amongst others, and meet the highest quality requirements such as IP 67, IP 69, UL 94 V0, FMVSS 302, UL 746 B (RTI), and thermal classification B – F.

With state-of-the-art production processes and plants, RAMPF guarantees the economical, quality-compliant, and ecological (ISO 14001) manufacture of its products.

RAMPF Polymer Solutions is a company of the international RAMPF Group based in Grafenberg, Germany.

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

http://www.rampf-group.com

Pressereferent

Telefon: +49 (7123) 9342-0

E-Mail: pr@rampf-group.com

![]()