“The previous M12 connectors have already been developed very close to the limits of feasibility. We have now checked all the adjusting screws once again to achieve the best results. Without a design using a digital twin, this would hardly have been possible," explains Martin Guserle, Head of Business Unit EPIC® Connectors at U.I. Lapp GmbH.

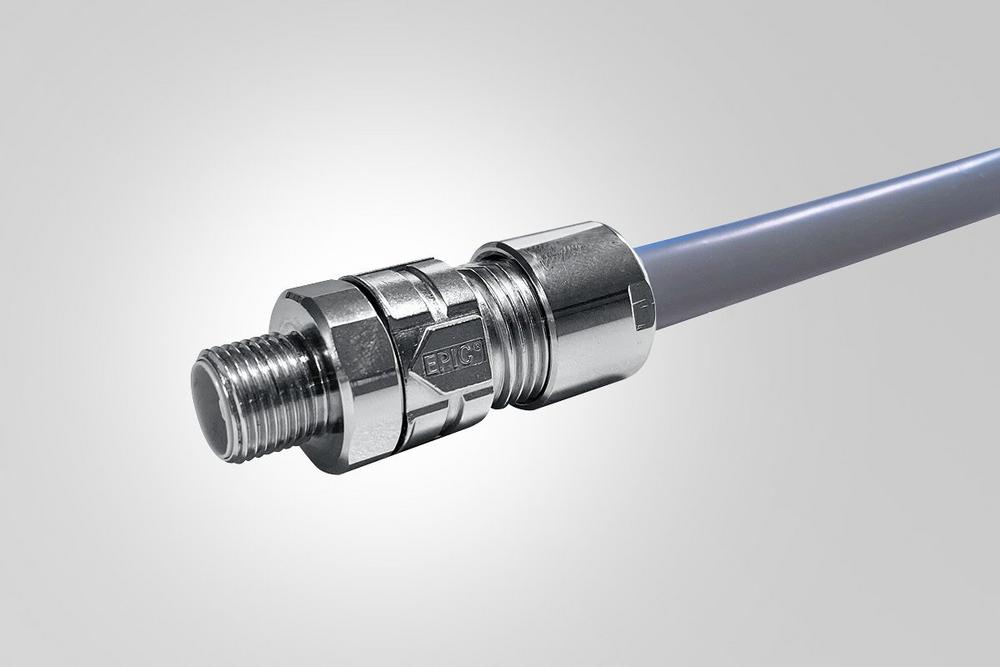

During development, the technical properties of the connectors were simulated using virtual models. The two M12K series for energy transmission up to 630V/12A and M12L up to 60V/16A were virtually put through their paces before producing the first 3D-printed model. This means that the limit of power transmission with increasingly smaller connectors is first evaluated virtually and then transferred to initial prototypes and series production. Compared to connectors previously developed by LAPP, this results in significantly smaller design sizes, yet with improved power transmission

The new EPIC® POWER M12L and M12K connectors have a wide range of applications. For example, they are suitable for small robots known as "cobots", which collaborate with humans in production or in the warehouse. Or for automated guided vehicles (AGVs), such as in the LAPP logistics centre in Ludwigsburg. Such autonomously driving transporters also involve tight spaces for all components. Use in I/O modules for PROFINET is another big field of application for the EPIC® POWER M12L connector. Hitherto, 7/8" connectors have been the standard power interface for the sensor/actuator distributor. The change from the old standard to the M12L enables boxes to be reduced in size by over 50%. The PNO has defined the M12 L-coded as the interface for the power supply for all PROFINET applications. This is the set standard for PROFINET devices such as intelligent motors or I/O modules. The M12 L coding offers the ideal conditions for this.

Martin Guserle: "We anticipate that the majority of new machines and systems will be set up with M12 L coding as the power interface in the future." The Automation Initiative of German Automotive Manufacturers (AIDA) has also already decided to set the M12L as the standard

Headquartered in Stuttgart, Germany, LAPP is a leading supplier of integrated solutions and branded products in the field of cable and connection technology. The company’s portfolio includes standard and highly flexible cables, industrial connectors and cable entry systems, customised system solutions, automation technology and robotics solutions for the intelligent factory of the future, as well as technical accessories. LAPP’s core market is in the industrial machinery and plant engineering sector. Other key markets are in the food industry as well as the energy and the mobility sector.

LAPP has remained in continuous family ownership since it was founded in 1959. In the 2019/20 business year, it generated a consolidated revenue of 1,128 million euros. LAPP (with the inclusion of its non-consolidated companies) currently employs approximately 4,575 people across the world, has 20 production sites and around 43 sales companies. It also works in cooperation with around 100 foreign representatives.

U.I. Lapp GmbH

Schulze-Delitzsch-Str. 25

70565 Stuttgart

Telefon: +49 (711) 7838-01

Telefax: +49 (711) 78382640

http://www.lapp.com

Telefon: +49 (711) 7838-01

Fax: +49 (711) 7838-2640

E-Mail: irmgard.nille@in-press.de

![]()