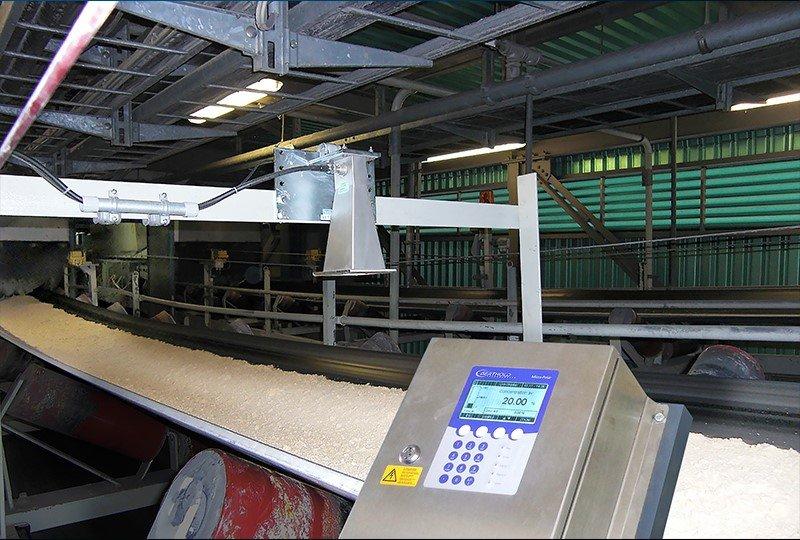

Continuous moisture measurement of gypsum from quarries allows product distribution in the storage silo to be optimized according to moisture content. Monitoring of moisture content after the storage silo and before firing allows improved control of kiln operation as a means to improve the quality of the finished product. The Micro-Polar moisture meter provides online measurement of the moisture content of gypsum transported by a conveyor belt to the intermediary storage before the kiln. Using microwave technology, a non-contacting measurement is made through the entire product height. This allows a representative online measurement even if the product on the belt comes from a mixture of different storage areas with different humidity levels. Microwave measurement is non-contacting; no sensor comes into contact with the product to be measured, which limits maintenance and avoids special cleaning. The measurement is not influenced by the colour or inhomogeneity of the measured product. Furthermore, the measurement is carried out on the entire product profile while traditional measurements only measure the surface of the material profile. In addition, the multi-frequency technique and the reference line enhance the stability and representativeness of the resulting measurement. Berthold’s Micro-Polar system is very easy to install. The transmitter has a large display and a user-friendly interface. Automatic calibration can also be performed on site.

These advantages are used to make critical applications more reliable:

- Improved thermal control the blast furnace operation

- Known moisture content when offering/ loading bulk solid material

- Wear-resistant and maintenance-free as measurement is non-contacting

- Non-contact measurement and no disturbance in the flow

- Easy to install or retrofit on existing conveyers

For further information please visit this link:

Measuring moisture measurement of gypsum – Berthold Technologies

Über die BERTHOLD TECHNOLOGIES GmbH & Co. KG

As a world technology leader in the field of radiometric measuring systems, Berthold products convince with outstanding measuring performance and reliability. The main fields of application are, for example, in chemical & polymers (etc. fertilizer industry), steel and power plants, mining & mineral processing, waste & recycling, refineries, paper, glass and as well as in the food industry (etc. sugar beets). In addition, microwave measuring systems for the determination of moisture and concentration belong to our extensive portfolio. The production of high-quality measuring systems for industry and research began more than 70 years ago in Bad Wildbad in the Black Forest.

Firmenkontakt und Herausgeber der Meldung:

BERTHOLD TECHNOLOGIES GmbH & Co. KG

Calmbacher Straße 22

75323 Bad Wildbad

Telefon: +49 (7081) 177-0

Telefax: +49 (7081) 177-100

http://www.berthold.com/process-control/

![]()