Due to its flame retardant properties and low smoke emission, it can be used in interior applications of aircraft or rail vehicles, among others. The maximum continuous operating temperature is up to 220 °C. Very low water absorption, excellent creep resistance even at elevated temperatures and high dimensional stability round off the property portfolio of this new TPUD. It is therefore also suitable for demanding applications in the aerospace, oil & gas, sporting goods or industrial sectors, while remaining cost-effective. These properties make the product perfect for highly automated processing routes such as ATL or AFP in combination with overmolding for complex geometries. Production start for the Tenax™ TPUD with PPS matrix is the first quarter in 2021.

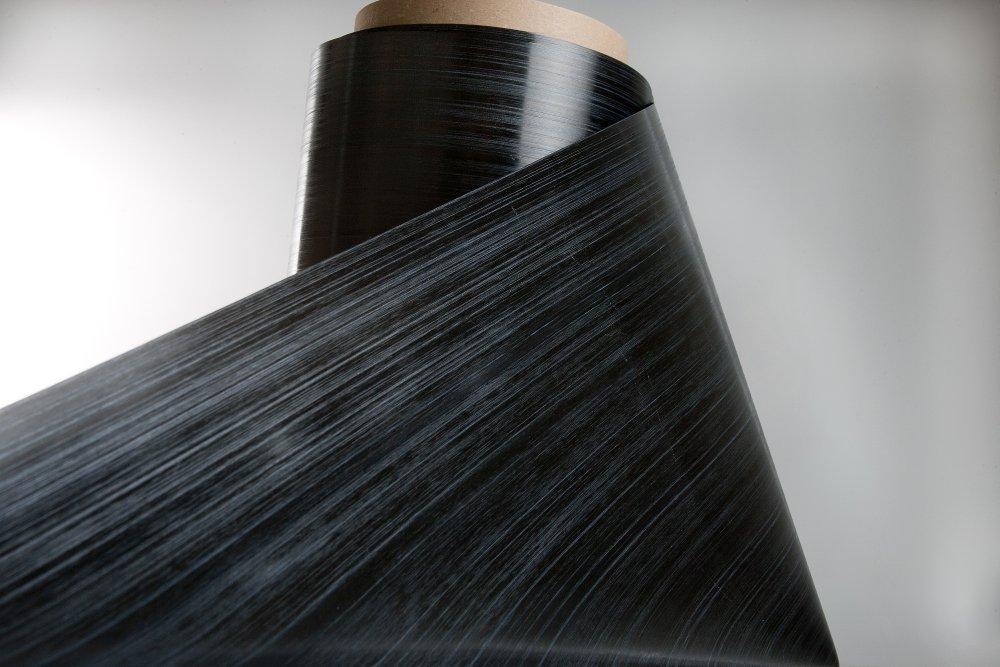

For almost 10 years, unidirectional tapes (TPUD) have been manufactured from carbon fibers and thermoplastics in Heinsberg, Germany. The semi-finished products have so far been offered with PEEK or PAEK – and PPS is now added to the list of available matrixes. PPS allows a lower process temperature compared to PEEK or PAEK. For the industrial market in particular, increasing the production rate to make processes more cost-efficient is a milestone.

In order to meet the demand of a wide range of application areas, Teijin’s Carbon Fiber Business offers various types of Tenax™ TPUD These differ not only in the matrix, but also in the Tenax™ Carbon Fibers used with varying tensile strengths and moduli. This makes it possible to find the optimum product even for high technical requirements. Depending on the Tenax™ TPUD type, they are available in a variety of fiber basis weights between 100 and 190 g/m² on roll lengths up to 2000 metres and in widths up to 24". Typical applications include aerospace, medical, automotive and oil&gas. They are suitable for a wide range of processing applications. Rapid processing cycle times of a few minutes can be realized without any problems.

About the Teijin Group

Teijin (TSE: 3401) is a technology-driven global group offering advanced solutions in the fields of environmental value; safety, security and disaster mitigation; and demographic change and increased health consciousness. Originally established as Japan’s first rayon manufacturer in 1918, Teijin has evolved into a unique enterprise encompassing three core business domains: high-performance materials including aramid, carbon fibers and composites, and also resin and plastic processing, films, polyester fibers and products converting; healthcare including pharmaceuticals and home healthcare equipment for bone/joint, respiratory and cardiovascular/metabolic diseases, nursing care and pre-symptomatic healthcare; and IT including B2B solutions for medical, corporate and public systems as well as packaged software and B2C online services for digital entertainment. Deeply committed to its stakeholders, as expressed in the brand statement “Human Chemistry, Human Solutions”, Teijin aims to be a company that supports the society of the future. The group comprises more than 170 companies and employs some 20,000 people across 20 countries worldwide. Teijin posted consolidated sales of JPY 836.5 billion (USD 7.7 billion) and total assets of JPY 1,036.4 billion (USD 9.5 billion) in the fiscal year that ended on March 31, 2021.

Please visit www.teijin.com

Teijin Carbon Europe GmbH

Kasinostraße 19-21

42103 Wuppertal

Telefon: +49 (202) 32-2339

Telefax: +49 (202) 32-2360

http://www.teijincarbon.com/

E-Mail: marketing@teijincarbon.com

Telefon: +81 (3) 3506-4055

E-Mail: pr@teijin.co.jp

![]()