In the 1950s, British engineer Sir Alistair Pilkington came up with an idea that was to revolutionize the glass industry: allow molten glass to flow onto liquid tin as a substrate. To this day, this “floating” – the tin bath – forms the basis of industrial flat glass production and thus is a decisive quality factor. Consequently, at CNUD EFCO GFT, it is always tailored to each customer’s requirements.

CNUD EFCO GFT delivers the complete tin bath with everything that goes with it. Together with its parent company, Grenzebach, which acquired CNUD EFCO GFT in late 2019, the Group is now a full-range supplier “from hot to cold”: from the tin bath to the annealing lehr to the cold end, from the coating technology to the transport of the final product to the warehouse.

The tin bath – endless fascination

The molten glass is fed into the tin bath, which contains liquid tin in an inert gas atmosphere. On the molten tin, the glass mass flows and is formed into an endless ribbon. By matching the bottom of the glass to the completely flat surface of the tin and simultaneously heating from above, a plane-parallel, distortion-free glass ribbon of high optical quality is formed. The glass temperature drops in the tin bath from 1,050 °C at the inlet to around 600 °C at the outlet, and the glass leaves the tin bath shaped and pre-strengthened.

New generation tin bath thanks to process simulation

CNUD EFCO GFT’s tin bath has been redesigned in all areas based on process simulation: from the optimized bath bottom profile to the flow-optimized atmosphere distribution through the roof, all factors of the tin bath affecting efficiency have been further developed. The result is a revolutionary tin bath tailored to the customer’s needs with the highest yield and quality while saving on investment and operating costs.

The de-drossing pocket at the end of the tin bath is also an important quality factor: it is placed on the side to remove the dross that accumulates in the outlet area. This prevents dross from sticking to the underside of the glass ribbon while it is being lifted from the tin bath toward the dross box.

The contaminated tin is passed through a refractory channel. The dross floating on the tin gets caught on a weir, is dammed up and can then be removed. The system is usually driven by a linear motor that generates electromagnetic fields and thus a flow in the direction of the de-drossing pocket. Alternatively, a paddle system can be used, which reduces the cooling effect – important in the production of special glass where cooling inputs must be avoided. Thus, the de-drossing pocket contributes immensely to the quality of the glass; without it, defects in the final product are almost inevitable.

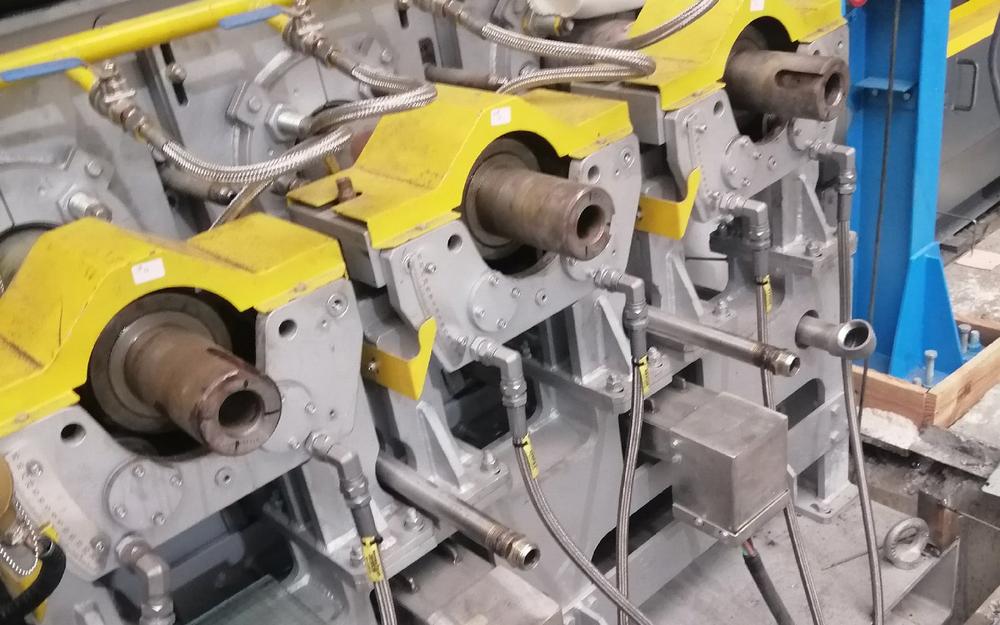

Where viscous glass is lifted from the tin bath: the dross box

The dross box is another indispensable component in the glass production line: here, the pre-strengthened and shaped glass floating on the tin is lifted out by three motorized rollers and transferred to the annealing lehr. The dross box also has the important task of sealing the tin bath atmospherically. This is done by means of graphite strips pressing from below against the rollers conveying the glass. Above the glass, curtains are used to seal the transition between the tin bath and the annealing lehr.

The dross box from CNUD EFCO GFT also features a particularly high degree of insulation. The result is less heat loss and a better – because more homogeneous – temperature distribution over the entire width of the glass. The temperature at the edge no longer deviates significantly from that in the center of the glass ribbon. This ensures better glass quality and reduces the risk of transverse breakage.

The most important feature of the CNUD EFCO GFT dross box is that it is particularly tight, so it minimizes oxygen ingress and thus prevents or reduces the oxidation (slag, dross) of the tin. This makes it possible to reduce the hydrogen content in certain areas, which in turn results in considerable savings in operating costs. The interaction of our dross box and de-drossing pocket enables production with the highest yield at reduced operating costs.

Next-level efficiency: the compact tin bath from Grenzebach and CNUD EFCO GFT

No space is wasted: the tin bath from Grenzebach and CNUD EFCO GFT is 6 to 9 meters shorter than most, as the cooling area in the tin bath is optimized – which means that, despite its compact dimensions, it produces the same yield. This space saving is crucial, especially for cold repairs, in order to make optimum use of the available space. This enables the company to offer tin baths that produce the same yield despite their compact dimensions. The tailor-made design also contributes to efficiency. The desired tonnage, the range of thicknesses and the glass quality: everything is taken into account in the design. As a result, customers are able to maintain productivity at the same level – or even increase it – while using fewer resources.

The advantages at a glance

- Lower CAPEX

The compact tin bath reduces investment costs across the board. A shorter building, less steel construction, less space and less tin (10 to 15 percent): all this adding up to considerable savings.

- Lower OPEX

In addition to the initial investment, the consumption of resources in operating the plant is also reduced, resulting in lower maintenance costs. Less heat loss, less inert gas required, less loss due to atmospheric leakage and less flaws in the glass, as well as a smaller free tin surface: these are advantages you enjoy throughout the entire life cycle of the plant. - Higher production capacity

This allows the tonnage of the glass production line to be increased in the event of a cold repair; that is, with an existing glass plant and available space – which means that you produce more output with the same size of tin bath. We will check and individually calculate exactly what and how much is feasible in each specific case.

Simulation maps the entire process in advance

It’s good to know in advance what you’re going to get. Therefore the complete tin bath is simulated in advance, optimized and agreed with the customer for the best possible results. In this process, it is possible for the first time to simulate all four parameters – atmosphere, tin, glass and temperature – with their mutual dependencies. In this way, valuable insights can be gained, which in turn are incorporated into the development and improvement of the technologies. The tin bath simulation: a milestone in the development of the tin bath.

United power to create new synergies:

Grenzebach and CNUD EFCO GFT have been supplying equipment for the production and further processing of industrial float glass from the very beginning. We have been a technology innovator since the 1990s. CNUD EFCO GFT was originally born of a merger between three pioneering companies: CNUD, EFCO and GFT.

- CNUD, has supplied annealing lehrs since the early days of float glass production.

- EFCO has delivered groundbreaking work in tin bath development, with a special focus on the tin bath roof.

- GFT is the expert in tin bath technology, but also in the entire glass manufacturing process, including media supply and the waste heat recovery system.

Today, well over half of all glass panes installed are produced with technology from Grenzebach and/or CNUD EFCO GFT. Deep process knowledge and decades of experience can produce even better results: Grenzebach and CNUD EFCO GFT jointly create added value for the international glass industry. Bundled competence for flat glass production means innovative technologies, a competitive edge through digitalization and energy-efficiency, creating the benefits of tomorrow.

Grenzebach is a leading automatization solution provider for the global glass, building material and intralogistics market. In addition, the company develops new application areas, such as friction stir welding, the automatization of industrial additive manufacturing and digital networking. The digitalization platform SERICY allows customers to develop their own future-proof digital know-how. Grenzebach ranks among the international technology leaders in its markets. The global manufacturing footprint with production sites in Germany, Romania, the US and China, as well as additional worldwide locations ensure customer support on-site. More than 3,000 systems installed in more than 55 countries stand for quality and reliability. Since the company opened its doors 60 years ago, it has been owned by the founding family. With an export ratio of more than 90 percent, Grenzebach is a global player.

Grenzebach Group

Albanusstrasse 1

86663 Asbach-Bäumenheim

Telefon: +49 (906) 982-2000

Telefax: +49 (906) 982-108

http://www.grenzebach.com/de/

Marketing Specialist

Telefon: +49 (906) 982-2068

Fax: +49 (906) 982-2108

E-Mail: lisa.reitschuster@grenzebach.com

![]()