Dennis Tiegs, COO A+W Clarity: “What’s special about A+W SmartFactory is that it can be scaled, which helps smaller operations get larger and large operations to automate further. Companies thus enjoy the benefit of the lean production approach from the very start."

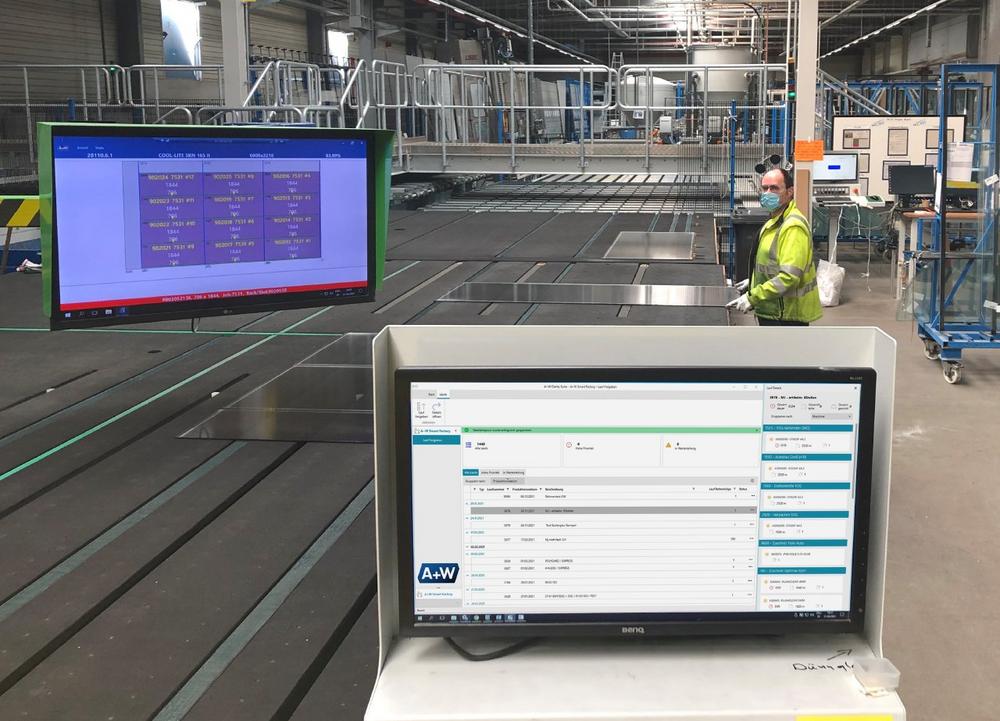

A+W SmartFactory is the top-level production system that coordinates the process flows for an optimized glass flow. The system is in a position to responsively control all coupled machines and software modules with the production data provided. Machines communicate constantly with the system via so-called A+W SmartFactory clients; this enables control of machine status and machine capacity.

According to the principle of backward scheduling, the dispatch requirements and thus ultimately customers control the production sequence. Planning is done in real time and can be adjusted at any time in the future if this should be necessary to accomodate rush orders, capacity bottlenecks, machine failures, etc. Dispatch generally doesn’t even notice this, so it’s almost always possible to make on-time deliveries. Vetrotech customers profit from improved performance and delivery reliability.

If there are no possibilities for direct machine communication, A+W SmartFactory clients function as imitation machines that can determine status and capacity per machine thanks to the integrated plant data collection. A control center provides the production manager and the general management with a wide variety of information from A+W SmartFactory, and if necessary, allows them to intervene directly in production, e.g. by manually adjusting production chains. Here too, precisely that is produced which is needed first in dispatch; rush orders are integrated without a problem, WIP (work in process) is reduced a great deal. This way, even less-automated companies can profit from this development.

The intelligence required for this lies only in the software that controls the communication between machines, and also between machines and human beings: a new industry standard on the path to Industry 4.0, which is optimized constantly by the expertise that flows from A+W’s pilot customers.

Dennis Tiegs says "Our customers‘ experience keeps improving A+W SmartFactory all the time." "That’s why we’re looking for more pilot customers to create a win-win situation: we optimize the customer’s processes, users incorporate their experiences, which helps design and further improve production systems of the future."

Learn more: -> https://blog.a-w.com/uk/on-the-path-to-industry-40

A+W Software for Glass and Windows

A+W is the global market leader for software in the flat glass industry and glass processing as well as the windows and doors business. The company develops ERP-, PPS-and op-timization software in order to make glass and window manufacturers even more efficient.

A+W solutions control and optimize the whole value chain, from basic glass to finished windows or facade elements. A+W products are suitable for small, mid-sized and large companies.

A+W optimizes its customer’s yield, reduces the production costs, shortens the lead times, improves the quality and thus increases customer satisfaction.

A+W has been active on the market for more than 40 years and sells its products worldwide. A+W cooperates with the most experienced and competent companies in the industry. This close networking helps A+W to provide always the best possible solution for its customer’s demands.

A+W is a wholly owned company of Constellation Software Inc, which is listed on the Toronto Stock Exchange under the symbol “CSU”. The Corporation ac-quires, manages and builds vertical market software businesses.

A+W Software GmbH

Siemensstraße 3

35463 Fernwald

Telefon: +49 (641) 96620-0

http://www.a-w.com

Senior Manager Company Communications

Telefon: +49 (6404) 2051-241

Fax: +49 (6404) 2051-877

E-Mail: michael.kuettner@a-w.com

![]()