Corona pandemic: How we overcame the crises

For a globally active commercial enterprise, the effects of the global and country-specific restrictions were immediately apparent. In the first half of the year, the company had to face additional challenges such as restrictions due to lockdowns in several countries, early inoperability and shutdowns of plants or the delays in movement of goods due to border controls. As a company of the Würth Group and a part of the Würth Industrial Network, the partner for C-Parts has built a strong industry network of more than 60 companies in over 40 countries and has a strong financial base granting it additional stability. Würth Industrie Service was able to cater to all the customers at any given point in time through its proactive approach, continuous communication with the suppliers, comprehensive supplier monitoring, adequate product provisioning and options to access alternative sources. The company looks at the future optimistically owing to the trust the customers have placed in its contactless supply systems and automatic procurement via E-Business solutions in the period of lockdown.

C-Parts management – holistic, sustainable, stable

The Covid-19 pandemic in 2020 has proven once again how important it is to have a stable C-Parts management and why various aspects and expertise in supplier selection are more important than ever to be able to cope up with the decline or peaks in demand for product groups. This is precisely why it is important to have a customised C-Parts supply directly at the point of need and place of use – regardless of whether for direct or indirect materials. With automated, digital and contactless technologies, the processes can be tailored to demand fluctuations quickly and promptly and can be operated flexibly in case of any changing circumstances. “Thanks to our multi-channel strategy, our customers can interact with us via different channels – personally and regularly through a contactless form of communication i.e. digital and electronic and we can provide our customers the procurement solutions they need for an optimal C-Parts management under all conditions, especially during a pandemic.” states Martin Jauss, General Manager of Würth Industrie Service.

Hence, the focus of the company is on processes and systems committing maximum innovation. With innovative RFID system solutions such as iPLACER®, a handy, battery-operated module with an integrated reader and transmitter as ordering and inventory management system as well as the study of an RFID pallet box, an open system for automatically triggering orders by continuously scanning the surroundings for RFID tags, Würth Industrie Service is expanding its portfolio by adding more solutions, which can help the users to digitalise and transparently design their entire delivery chain. The study on ORSY®mat CBL, a vending machine for supplying cables, wires, cords and installation material to the customers, or even ORSY®mat WGT, a system with integrated weighing cells for automatically ordering almost all auxiliary and operating materials used as personal protective equipment, assures maximum certainty in materials management. In all these scenarios, the focus is on maximum security of supply. To ensure utmost safety in the workplace, the company has introduced professional hygiene solutions to its workplace systems of the CPS®IWS product line in the wake of the pandemic.

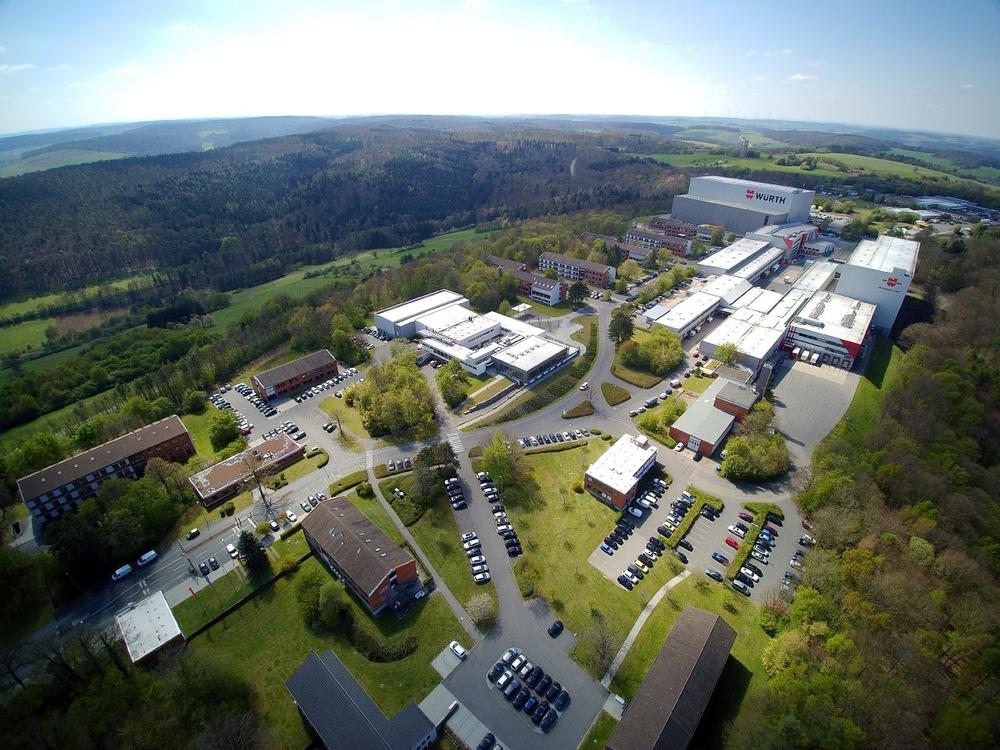

Ready for the future: Würth Industrial Park to a new level

From its formative years to this day, the company has invested more than 366 million euros for ensuring maximum supply security and delivering high quality products, services and systems. In addition to increasing the storage capacity, it has introduced innovative technologies to its existing systems. With the measures being currently implemented and planned, Würth Industrie Service has taken significant steps for a great future customer supply and thus unlocked the potential in the areas of automation, digitalisation as well as robotics.

Internationalisation as a success factor – WINWORK®

Würth Industrial Network (WINWORK®) has also developed significantly in 2020. In more than 60 companies. In more than 40 countries. With more than 5000 employees worldwide. Thus, it was possible to provide comprehensive customer consulting as well as ensure a seamless flow of all the important information while maintaining the company’s high standard of quality and systems at all times across individual production sites and requirements. As a result, the company was able to achieve a turnover of 1.587 billion euros in total globally in the previous fiscal year.

Over 1,700 employees: The key to success

“Our most valuable asset are our employees.” believes Mr. Bürkert. Despite the Corona crisis, the company did not make any structural staff cuts; on the contrary: the number of employees is still more than 1,700. The apprenticeship of junior employees plays a significant role here. In 20 job profiles, 200 employees are attending an apprenticeship or a dual study at Baden-Württemberg Cooperative State University.

One step further: digital and virtual

The fact that Würth Industrie Service is driving digital transformation is proved not only by the technologies in automated C-Parts management but also by the opportunity to interactively experience the range of services offered by the company. The virtual showroom “WIS Virtual Experiences” presents system solutions as well as product range for an efficient C-Parts management as well as offers a suitable setting for customer visits. Even the 18th Ketterberg dialogue was held virtually for the first time ever. In the light of the Corona pandemic, the company opted for alternative methods in addition to the traditional formats of personal customer contact. Digital formats for events and webinars are contributing significantly to interactive networking.

Prospects 2021

At the beginning of 2021, there was an organisational change in the Würth Group. Rainer Bürkert, former Executive Vice President of Würth Group and Managing Director of Würth Industrie Service, has been appointed to the Central Managing Board of the Würth Group w.e.f. 15.02.2021. He will be responsible for the entire Würth Line Industry worldwide.

Profitable growth drives all the activities of Würth Industrie Service and thus defines the strategic goal. The beginning of the first quarter of 2021 is already marked by increased demand in the market, which allows the company to look optimistically to the next few months. Owing to a strong financial base, a strong and technological industry network from more than 60 companies in over 40 countries, the company is well positioned to deal with the crisis and, especially after it is overcome, to provide its customers with innovative system solutions and products reliably and safely.

Within the Würth Group, Würth Industrie Service GmbH & Co. KG is responsible for the supply of the industrial sector. Since its foundation in 1999, Würth Industrie Service is located at the Industriepark Würth in Bad Mergentheim, Germany with over 1700 employees. As a full C-Parts provider, the company offers its customers a specialised product range of over 1,100,000 items: from screws, connection and fastening technology, tools to chemical-technical products and occupational safety. In addition to the extensive standard range, the strength of the company lies in its customer-specific, logistical and dispositive supply and service concepts as well as in special parts. Under the service brand “CPS® – C-Product Service”, the company offers modular solutions, which are customised as per customer-specific requirements. Thereby, the consumption-based and demand-based systems significantly rationalise the processes for purchase, logistics and quality assurance and enable the customers to procure small parts in a cost-optimised manner. Logistic and dispositive services such as shelving systems with scanners or a just-in-time supply using Kanban bin systems contribute significantly to increasing the productivity.

Würth Industrie Service GmbH & Co. KG

Drillberg

97980 Bad Mergentheim

Telefon: +49 (7931) 91-0

Telefax: +49 (7931) 91-4000

http://www.wuerth-industrie.com/pressebox

Telefon: +49 (7931) 91-0

Fax: +49 (7931) 91-4000

E-Mail: info@wuerth-industrie.com

Leiterin Marketing

Telefon: 07931 91-1153

E-Mail: stephanie.boss@wuerth-industrie.com

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (7931) 91-3409

E-Mail: pia.schmitt@wuerth-industrie.com

![]()