The directive 2014/34/EU (ATEX) of the European Union regulates the market for explosion-proof electrical and mechanical devices, components, and protective systems. It is relevant for numerous industries and applications, including the filter industry. Here, the static charge inside the filter during cleaning can lead to a spark, which in the worst case could cause an explosion in the filter.

In order to prevent this, RAMPF Polymer Solutions has developed conductive casting compounds for use in potentially explosive applications. The polyurethane systems have an excellent conductivity of 0.03 MOhm/cm, whilst at the same time exhibiting a very low mixing viscosity and therefore very good flow behavior. As a result, users do not need any complex conveyor systems, and potting applications can be easily processed.

The casting compounds are available in Shore hardness A 85 and D 80. Further benefits are high chemical resistance and good machinability.

RAMPF – holistic partner for air and oil filter production

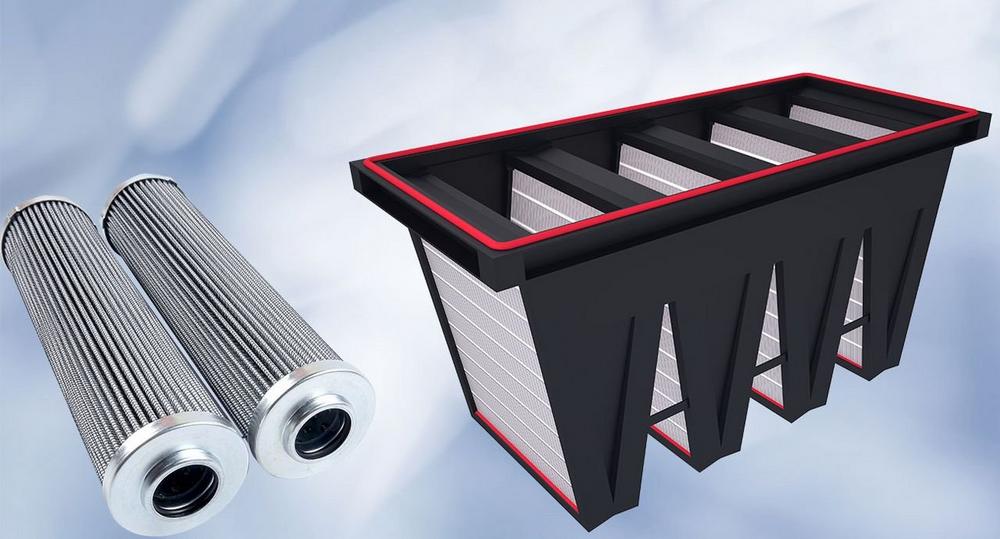

For the filter industry, RAMPF Polymer Solutions develops and manufactures customized two-component sealing systems based on polyurethane, two-component potting compounds based on polyurethane and epoxy, and reactive hotmelt systems.

Michael Wahl, Business Center Director Casting Resins & Elastomers – “Our products exhibit good ad-hesion to metal and plastic, high temperature resistance, and good flow properties. Together with inno-vative mixing and dispensing technology from our sister company RAMPF Production Systems, we offer our customers holistic solutions, supporting them from product development to use in production.”

RAMPF Polymer Solutions GmbH & Co. KG is a leading developer and manufacturer of reactive resin systems based on polyurethane, epoxy, and silicone. The company also possesses comprehensive expertise in application technology.

The product portfolio of RAMPF Polymer Solutions includes liquid and thixotropic sealing systems, electro and engineering casting resins, edge and filter casting resins, and adhesives.

Research and development are highly prioritized: Based in Grafenberg (near Stuttgart), Germany, the technology pioneer and quality leader has laboratories and facilities for application technology within its spacious Innovation Center. Every day in the RAMPF Innovation Center, new products are developed, existing products are adapted to specific customer requirements, and a huge range of material combinations are tested.

The materials created in the laboratory are tested in the application technology department, where samples are also made for customers to further enhance product quality and reduce the time to series production. Naturally, customers also receive support during the product rollout phase and production process.

RAMPF Polymer Solutions attaches particular importance to renewable raw materials during the initial research phase. Biopolyols are developed in cooperation with sister company RAMPF Eco Solutions. The potential use of recycled polyols in the composition of new products is also closely examined.

RAMPF Polymer Solutions is a company of the international RAMPF Group based in Grafenberg, Germany.

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

http://www.rampf-group.com

PR

Telefon: +49 (7123) 9342-1045

Fax: +49 (7123) 9342-2045

E-Mail: Benjamin.Schicker@rampf-gruppe.de

![]()