At the end of 2020, (scheduled launch date: 24 November 2020) STEGO is launching its new IIoT platform: STEGO CONNECT. The cloud service is a springboard into Industry 4.0 for small- and medium-sized enterprises (SMEs). The IIoT-based solution promises to reduce the initial hurdles in individual digitalisation projects, particularly for SMEs. The company, based in Schwaebisch Hall/Germany, uses IO-Link technology to achieve this. And STEGO CONNECT provides its integrated edge computing for fast, seamless data exchange with the cloud – a vital feature to ensure independence from constant internet connection.

Digitalisation-as-a-Service

“STEGO CONNECT brings users straight to the point where digitalisation starts to be fun.” Dominik Deschner, Head of Software Development at Stego, explains that the approach offers an easy and intuitive method for automating applications. When it comes to IT infrastructure, even companies open to digitalisation face challenges. Resources, time or IT expertise are often lacking in companies, such that expertise for cloud connection and data management needs to be bought in from external consultants and service providers. STEGO CONNECT is positioned as a solution ready for immediate use. Users pay a monthly “rental” subscription to access the STEGO CONNECT cloud and get started with their own Industry 4.0 project with a fully-established IIoT platform. There is no need for any time-consuming, expensive set-up. Users can focus entirely on their projects.

Easy set-up and networking

The Industrial Internet of Things (IIoT) always begins with network establishment. STEGO CONNECT makes initial set-up easy for users. Plug & Connect is the motto for effortless integration of any IO-Link device into the IIoT platform. Connected devices are automatically detected, without any user intervention, and included in the central device management module. Zoomable visualisation of the device hierarchy also provides the user with a drill-down overview of extensive and complex IO-Link device installations. The first step in the virtualisation of the user’s application is complete. The functions and start parameters of the connected IO-Link sensors and actuators are now also stored in Connect and ready for further adaptation.

Knowledge acquisition from data

Users now parametrise the connected IO-Link devices in accordance with the respective individual requirements that they want to control centrally in the cloud. A continuous stream of data is collected and processed in real time on the edge computer in the STEGO CONNECT system platform. Users receive an immediate virtual image of their actual application as a decision-making tool for automations and alerts. A range of visualisation options in the freely configurable dashboard, as well as export functionalities, give the user the freedom to use the data collected to gain knowledge about the performance of their application scenario. Thus, data is used as a basis for fault detection, fault correction and optimisation. Condition monitoring and remote access are achievable objectives, which are easy to accomplish using the STEGO CONNECT control functions. The unique feature of STEGO CONNECT is its ability to not only collect IO-Link data but to also use it to specifically and automatically control IO-Link actuators. All parameters for this can be configured at edge computing level from the cloud.

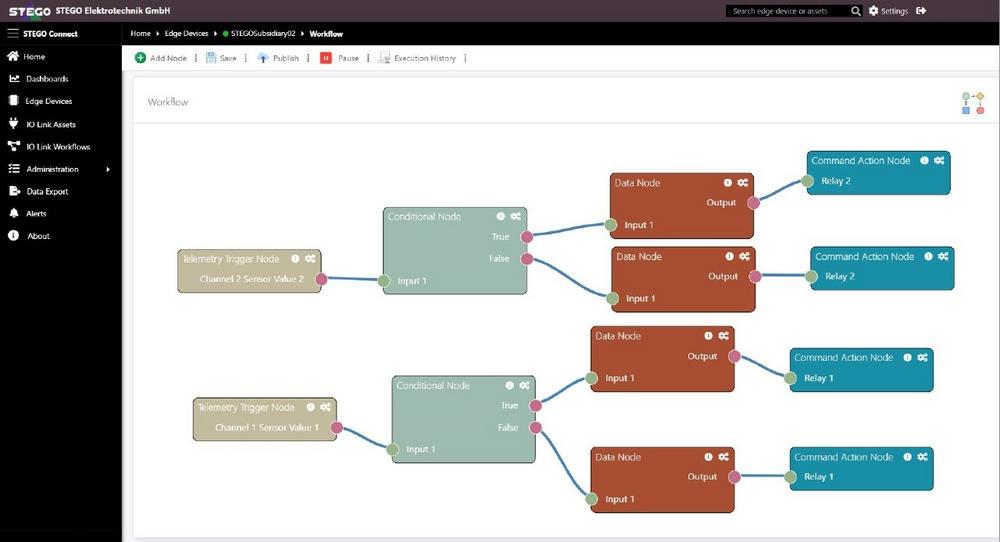

Workflows via drag & drop

In the IIoT, every physical site is just an IP address away, regardless of whether it is on your factory premises or in any remote location on the planet. The central control of localised systems ensures that the people responsible are constantly “on site” in genuine environmental conditions and can re-adjust their system according to requirements. Systems are parametrised and configured in the cloud. It is easy to create complex workflows with STEGO CONNECT using the intuitive drag & drop editor. Even users without any programming knowledge can set up complex processes that trigger control commands and alerts based on sensor data or processed data. The combination of resources in STEGO CONNECT is unlimited. Every connected sensor and actuator is automatable from the cloud with full flexibility. And in addition, manual override of the hardware is also possible from inside the cloud.

Intuitive, cross-manufacturer IIoT ecosystem

In summary, STEGO CONNECT is a new, smart ecosystem in the form of an IIoT platform solution. The crucial advantage lies in it being independent from any manufacturer. IO-Link sensors and actuators from any manufacturer are reliably integrated by STEGO CONNECT into an intuitive automation system. STEGO offers a subscription package for its cloud service to mark the launch of its IIoT platform solution. The business model is priced at a monthly fee of € 99 for each edge box installed in the system. There are also plans to launch an enterprise solution in the near future, which offers consultancy services for implementation and customised software programming for customers, as well as a white label option.

About STEGO CONNECT

STEGO CONNECT is the intuitive, cross-manufacturer IIoT platform solution for IO-Link devices. As an integrated digitalisation solution, STEGO CONNECT provides easy and fast access to Industry 4.0 applications based on IO-Link technology. High-performance integrated features are available for individual automation solutions: cloud connection, device management, data management, edge computing, workflow editing, central parametrisation and configuration, dashboards, alerts and sensor/actuator control. STEGO CONNECT is available as Software-as-a-Service and is specifically optimised to enable easy access for small-and medium-sized businesses to the world of Industry 4.0.

STEGO Elektrotechnik GmbH

Kolpingstraße 21

74523 Schwäbisch Hall

Telefon: +49 (791) 95058-0

Telefax: +49 (791) 95058-45

http://www.stego-group.com/de

Werbung & PR

Telefon: +49 (791) 95058-181

E-Mail: soerthel@stego.de

![]()