* ALD: Abbreviation of Atomic Layer Deposition. This is a thin-film deposition technique capable of precisely controlling the thin-film thickness and structure by forming atomic layers one by one and is widely applied in the manufacture of semiconductor devices.

<What is MCP?>

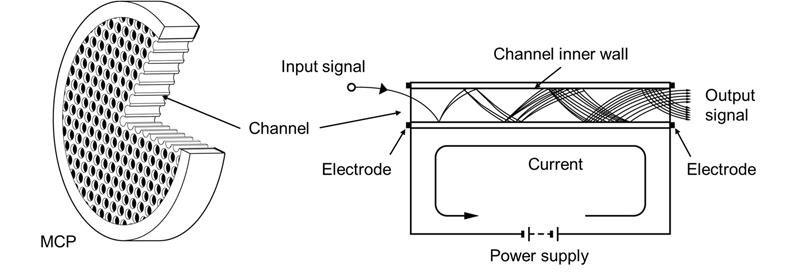

The MCP is an electron multiplier for two-dimensionally detecting and multiplying input signals such as ions, and is used in mass spectrometers and SEM. Basically it is a thin plate or disc having a great many fine glass capillaries or channels with an inner diameter of about 10 micrometers (micrometer is one-millionth of a meter). The inner wall of each channel is processed to convert input signals into electrons and multiply them. The voltage applied across an MCP creates an electric field in each channel to accelerate the electrons so that they strike the inner wall of the channel several times while being multiplied by secondary emission, and the multiplied electrons are then output as a large signal.

<Overview of developed product>

This newly developed ALD-MCP uses absolutely no materials containing lead which is a harmful substance restricted by the RoHS directive. Yet the ALD-MCP offers noise reduced by half and gain increased to twice that of conventional MCP.

MCPs usually use lead glass to impart better electrical characteristics to the lead reduction layer in the plate. Up to now we have developed, produced and sold high-quality MCPs based on our advanced technologies for glass processing and material design. In recent years, there is a growing market need for MCPs that do not contain lead which is a substance restricted by the RoHS directive. To meet this need, we have been working to develop a glass plate containing no lead and also develop technologies for depositing resistive films to give the plate the required electrical characteristics and also form secondary electron multiplier films to multiply electrons by secondary emission.

We reviewed the glass plate materials starting from scratch and eventually employed borosilicate glass that is highly resistant to heat, chemically stable, and easy to process. We also optimized the composition of glass to enable high-precision processing and developed a glass plate that does not contain lead yet has quality equivalent to conventional MCP. This also led to successful reduction of noise mainly caused by gases generated from the lead reduction layer which has been a problem with conventional MCP. Our unique film-forming technology applying ALD allowed us to deposit a resistive film and a secondary electron multiplier film with extremely high uniformity on the inner wall of each micro channel, which has been a difficult task up until now. All of this means we can now offer a low noise and high gain ALD-MCP that does not contain lead.

MCPs are used in mass spectrometers and SEM to enhance their performance by multiplying input signals such as ions. The ALD-MCP is likely to replace conventional MCPs that contain lead. The ALD-MCP also offers noise reduced by half, and gain increased to twice that of conventional MCP. So measurements can now be made with higher sensitivity without increasing the supply voltage, in other words, the same analysis results can be obtained by using a lower voltage which will extend the product service life and make it easier to use.

We will continue to develop various types of ALD-MCP to meet market demands for a broad and diverse range of applications.

<Main developed product features>

1. Glass plate using no substances restricted under the RoHS directive

The RoHS directive from the EU restricts use of specified hazardous substances in electrical and electronic equipment. It prohibits the sale of electrical and electronic equipment containing specified amounts of restricted substances in the EU market. In view of this, we employed borosilicate glass as a replacement plate material for lead glass and optimized the composition of the glass to develop a totally lead-free glass plate that has the same quality as those used for conventional MCP.

2. Low noise and high gain

Using borosilicate glass as the glass plate material gives the added benefit of suppressing noise generated mainly by gases from the lead reduction layer to one-half that of conventional products. The gain on the other hand is increased to twice that of conventional products while maintaining high operational stability. This is accomplished by a resistive film with good temperature characteristics and a secondary electron multiplier film with high stability under different environmental conditions, both of which are uniformly deposited on the inner wall of each channel by our unique film-forming technology that applies the ALD technique

<Development background>

Mass spectrometers are sophisticated instruments used to analyze the type and quantity of atoms and molecules contained in a sample by measuring their mass by irradiating the sample with an electron beam or laser to ionize the atoms and molecules. SEM is a type of microscope that allows observing the surface of a sample in much finer detail than optical microscopes by utilizing the electrons reflected or generated on the surface of the sample scanned with electron beams. In mass spectrometers and SEM devices, MCPs are used to amplify the input signals and enhance instrument performance. However, conventional MCPs contain lead which is a hazardous substance under the RoHS directive so there has been a great demand for high performance MCPs that do not contain lead.

Hamamatsu Photonics Deutschland GmbH

Arzberger Str. 10

82211 Herrsching am Ammersee

Telefon: +49 (8152) 375-0

Telefax: +49 (8152) 375-199

http://www.hamamatsu.com

Public Relations

Telefon: +49 (8152) 375-185

Fax: +49 (8152) 375-199

E-Mail: rfritsch@hamamatsu.de

![]()