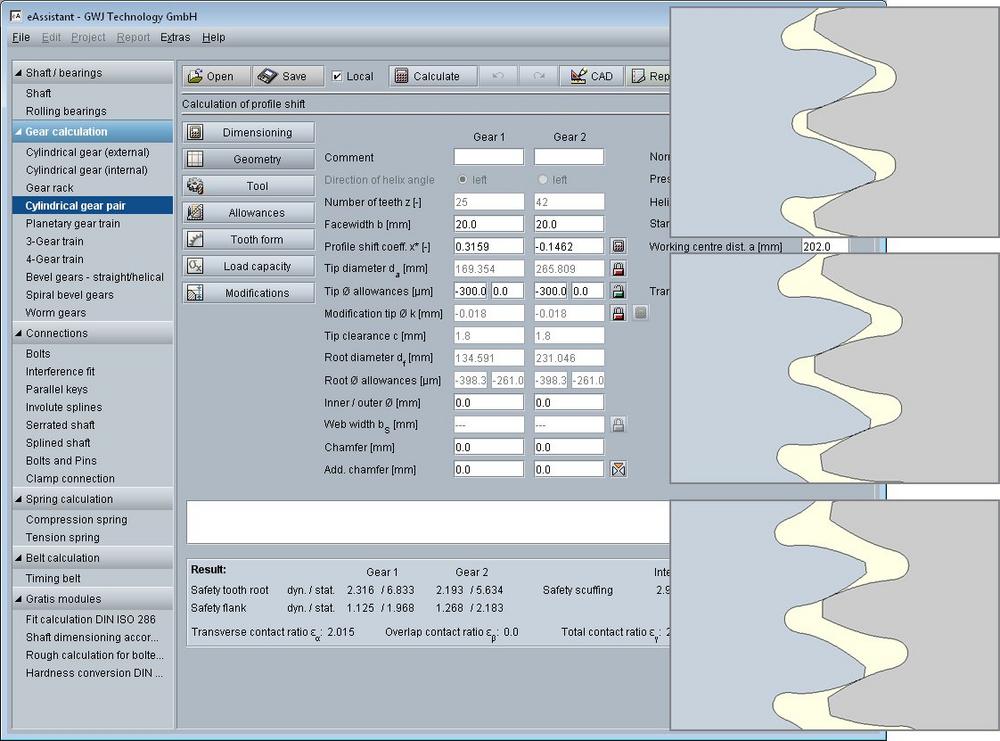

In addition to various dimensioning functionalities for the distribution of the profile shift, a new function for disconnecting the centre distance from the profile shift was added. By using the function "Fixed working centre distance (recalculation)", the profile shift coefficients can be defined independently from the centre distance. This enables, for example, the calculation of existing gear pairs that are to be installed in the housing with the "wrong" centre distance. Transverse contact ratio, backlash and load capacity are also calculated correctly in this case. This function can also be used for the calculation of small-module gears.

The functionality of tools with shifted profile reference line has been extended. Additionally to the addendum coefficient haMP0* of the shifted profile, the dedendum coefficient hfMP0* is displayed and visible in the calculation report. The dedendum coefficient hfMP0* can also be defined by clicking the "Lock" button so that the dedendum coefficient hfP0* of the converted, non-shifted basic rack profile is always 1.0 according to DIN 867.

The option "Full radius" for the tip form of gear shaper cutters has now also been added to hobs.

For the definition of load spectra, the user can specify the face coefficient KHbeta and the temperature for each load case. This enables the automatic transfer of values directly from the system extension "SystemManager" to the "Cylindrical gear pair" module in the background. The user can see directly the effects of flank modifications on the root and flank safeties of the gear in the system.

In addition to the common calculation methods for the load capacity DIN 3990, ISO 6336 and ANSI/AGMA 2101, the calculation method VDI 2736 for plastic gears was added to the cylindrical gear module.

Visit www.gwj.de and www.eAssistant.eu for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date. Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de

![]()