- New sealing unit for pallet strapping machines

- Secure strapping for bulky and heavy timber and construction products

- Infinitely adjustable strap tension up to 7000 newtons

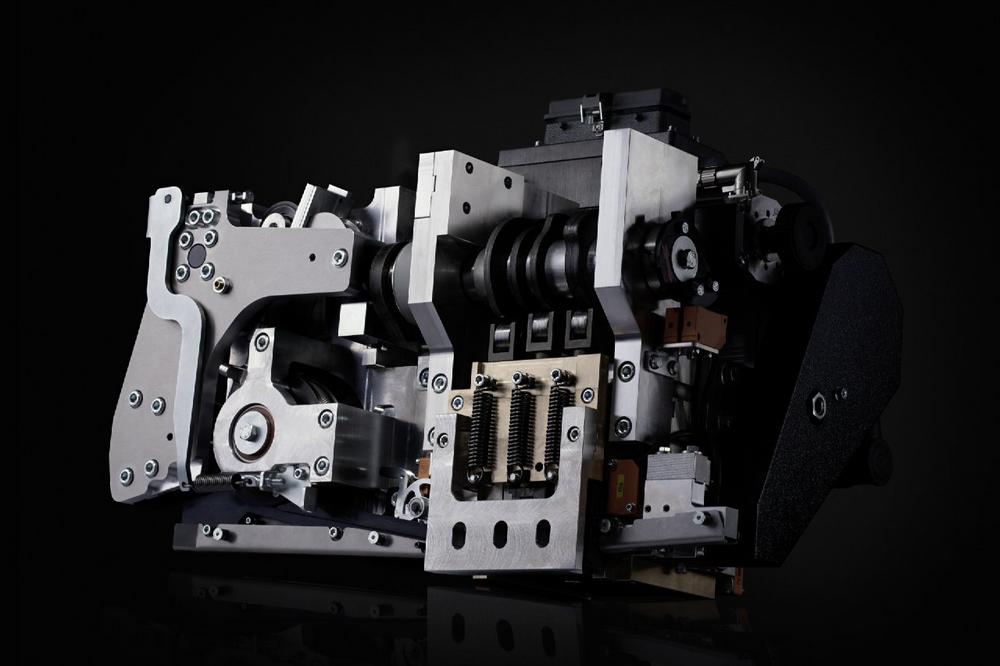

Mosca is flexing its muscles with a new high-performance sealing unit for heavy products in the timber and construction industries. With a tensile force up to 7000 newtons, the sealing unit works with strapping materials up to 19 millimetres wide and 1.27 millimetres thick. It can be integrated into Mosca pallet strapping systems. Machines that have a different high-performance sealing unit installed can be easily upgraded. Mosca HL-Sealing Unit features include a strapping control switch that checks each strapping cycle and highly reliable sealing provide added user safety.

From bulky wooden planks, to heavy paving stones and large sheets of steel – the timber and construction industries place high demands on transport securing systems. Mosca’s new high-performance sealing unit meets these needs with up to 7000 newtons of tensile force. "Heavy and bulky products require wider straps for secure transport," explains Mosca CEO Timo Mosca. "Straps with a width of 19 mm reliably secure even the heaviest products. The new Mosca high performance sealing unit enables customers to use wider straps in standard Mosca pallet strapping systems". This high-performance sealer handles strapping with a width of 19 mm and a thickness of up to 1.27 mm – and thus complements the range of high-end sealing units designed for 12 or 15 mm straps. Companies using Mosca pallet strapping machines can now their sealing unit and strapping material based on their heaviest products. They can also save energy by using different sealing unit variants on multiple lines. The control software makes it easy to adapt the machine when customers require less than the maximum strap tension.

Optional for all Mosca pallet strapping systems

The new sealing unit is currently installed in the Mosca KOV-111-16, KOV-315 and MK-50 – a machine that was primarily used in the ceramics industry and is now suitable for applications across the entire construction sector. Andreas Ding, product management team leader at Mosca, explains: "The high-performance sealing unit can be installed in virtually all of our vertical and horizontal pallet strapping systems. If customers have a different high-performance strapping unit in their system, we can easily upgrade their machines."

Safe and reliable strapping

The sealing unit operates with low-noise friction welding. An extremely safe strapping process is a key advantage of the high-performance aggregate when it comes to strapping heavy and bulky products. The strength of the seal is up to 80% of the tensile force of the strap used. A strapping control switch checks to ensure the strapping was successful before the product is discharged from the machine. This way, users can rely on perfect strapping, especially in fully automated processes. The strap protrudes slightly beyond the seal in the running direction to secure the full length of the seal.

Easy maintenance and space-saving storage of spare parts

The modular, open design of the sealing unit is a real advantage if parts need to be serviced or replaced. Components can be quickly and easily removed without tools, saving time for operators and maintenance technicians. Another advantage is that many of the same components are used in Mosca’s 12 mm, 15 mm and 19 mm high performance sealing units. Customers who have several machines in operation need to stock significantly fewer spare parts.

Mosca GmbH is a system supplier, developer and producer of high-quality strapping machines, strapping materials and safety systems for transporting goods for professional and industrial use. The machine portfolio ranges from universal devices with a wide range of applications, to fully automated high-performance machines that can be integrated into any higher-level automation line. Mosca produces strapping material out of PP and PET in one of the most modern sites in Europe. Mosca’s international distribution, service and consulting network enables global service for customers. Based in Waldbrunn (Germany), the family company was founded in 1966 and is present in 16 countries with 19 offices and six production sites in Germany, Malaysia, Canada and USA. It employs over 1000 employees. With continuous new developments, the strapping experts have maintained quality and technology leadership in the strapping sector for more than 50 years. Further information can be found at www.mosca.com

Mosca GmbH

Gerd-Mosca-Strasse 1

69429 Waldbrunn

Telefon: +49 (6274) 932-0

Telefax: +49 (6274) 932400-118

http://de-de.mosca.com/

Werbefachfrau für Online Marketing

Telefon: +49 (6274) 932-317

Fax: +49 (6274) 932400-317

E-Mail: nicole.frey@mosca.com

PR-Seniorberaterin

Telefon: +49 (6221) 1877912

Fax: +49 (6221) 90574-11

E-Mail: mosca@commhaconsulting.com

![]()